Research Article - (2025) Volume 14, Issue 1

Received: 03-Mar-2020, Manuscript No. JEES-23-7932;

Editor assigned: 06-Mar-2020, Pre QC No. P-7932;

Reviewed: 20-Mar-2020, QC No. Q-7932;

Revised: 06-Feb-2025, Manuscript No. R-7932;

, DOI: 10.37421/2332-0796.2023.12.47

, QI Number: JEES-23-7932

Citation: Asghari, Hamireza and Farzad Javanmardi. "Introducing a New Controller for Wind Turbines Aiming at Improving Quantity and Quality of Productivity Power." J Electr Electron Syst 14 (2025): 47.

Copyright: © 2025 Asghari H, et al. This is an open-access article distributed under the terms of the creative commons attribution license which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

The purpose of the present study is to introduce a new controller for wind turbines aiming at improving the quantity and quality of productivity power. The energy market is a competitive market in which producing electricity in wind power plants provides users with novel advantages than its production in fossil fuel power plants. Among the advantages of wind power plants is that during their lifespan, they produce fuel without any cost. Although the cost of other sources of energy production increases within years. Using wind power to produce electricity, especially multi-megawatt capacities, is the only economical method than other production methods based on recyclable energies (solar, biomass, geothermal, waves and fuel cell). It is necessary to mention that an increasing proportion of recyclable energies in the production of electrical power is among the midterm and long term strategic policies of many countries. Wind power has increased and due to various reasons attracted the public’s attention apart from its new competitive costs. Wind turbines can produce real energy and megawatt which are useful in the enhancement of transportation performance and confirmation of useful voltage. The nature of what is distributed through wind makes generators closer to consuming centers and removes losses of energy transportation.

Wind turbines • Quality • Productivity power • Control • Energy

Using sources of fossil and nuclear fuels needs high cost and increasing environmental pollution and its destructive consequences, therefore the emergence of energy crisis phenomenon in the world and advancement of wind power transformation technology to electrical energy has led to a reduction in its cost have made using wind power inevitable. Transformer systems of wind power to electrical energy has been widely used in commercial level since 1975. Nowadays, the technological progression of microcomputers and semiconductors has made using modern controlling systems possible and as a result production of electrical power with high quality has been created through wind power. Experience of installation and setting up wind power plants in industrial counties especially in America and Denmark have shown that the cost of these systems is comparable with the cost of traditional and common methods of producing electrical energy.

The main purpose of a power system is to supply electrical energy for network loads with high quality and to produce electrical power intervals. To enhance the quality of electrical energy it is necessary to control different quantities of power systems such as setting up, unplugging, productivity in a state of constant power. According to the nature of wind speed variations during different times, it is important to create a controlling state for power systems including wind energy transformers into electrical energy. Different components of a wind power system consist of: Wind turbines, generator, pitch angle controller of impeller and stimulation system, each component has different types and used based on its model. Thus considering the geographical location of Iran and the importance of recyclable energies, this study investigates this issue. Since the increasing speed of wind makes the turbine turn faster (turbine with variable speed) it is possible to get more power from winds with faster speed. This issue has led to more efficiency of the machine, as applied power on types of machinery eliminates these high speeds. These types of machinery also become cheaper and safer. Also this issue priorities present turbines. These turbines produce 4 times more energy with only 2.5 times more costs. Wind power has increased and due to various reasons attracted the public’s attention apart from its new competitive costs. Wind turbines can produce real energy and megawatt which are useful in the enhancement of transportation performance and confirmation of useful voltage. The nature of what is distributed through wind makes generators closer to consuming centers and removes losses of energy transportation. The modular nature of wind power plants and the speed of their establishment considered a valuable purpose for flexibility in the designation. Since achieved fuel is free and wind sources are predictable, costs of wind power are probably predictable and estimable fuel offensive fluctuations aren’t vulnerable and also not available [1].

Statement of the problem

According to a variety of human needs concerning energy and the impossibility of direct use of many primary energy resources, humans have managed to change or transform these energies based on their needs into their desired energy such as electrical energy. Electrical energy mainly produced by fossil fuels. On the other hand, fossil fuels, as well as limited lifespan, may cause environmental problems. Therefore it has been recommended to use recyclable resources.

After increasing oil cost in 1995, developed industrial nations forced to consider energy issues serious and it has been the beginning of long term plans in saving and optimizing energy consumption. In other words, using sources of recyclable energy especially wind power has been considered in these countries’ agendas. The most important problem while using wind turbines is how to control them.

Using wind power to produce electricity, especially multi-megawatt capacities, is the only economical method than other production methods based on recyclable energies (solar, biomass, geothermal, waves and fuel cell). It is necessary to mention that an increasing proportion of recyclable energies in the production of electrical power is among the midterm and long term strategic policies of many countries. The development of wind power plants in many countries needs direct and indirect supports from the government. Regarding private costs of wind and fossil power plants, it is not economical to develop wind power plants to produce electricity in Iran, so they are becoming more economical, but if social costs of fossil power plants containing negative effects considered as the basis of comparison, production cost will be less in wind generators than in fossil ones and the resultant electricity may be used as a sustainable energy in sustainable economicsocial development of country. Using wind power has caused flourishing and prosperity besides new job opportunities in Iran and finally, through localization of wind power, the country’s. Economics will more improve. Based on internet investigations of Iran Ghalam-e sabz: Through the transformation of gas power plants into wind ones leads to saving of 805 thousand m3 gas. Investigations of new energies organization show that a wind turbine with 660 kW capacity can produce 2 million and 330 thousand kW/h energy per year. Through substitution of wind turbines, 1 thousand and 140- ton pollutants diminish annually. This report demonstrates that the cost of per kW/h produced electricity by the wind power plant is 308 to 440 rials, however considering the real cost of fuel, the real cost of per kW/h produced electricity is 510 rials in the gas power plant. Due to the low cost of natural gas in Iran and paying much subsidy to this energy, the final cost of produced electricity utilizing subsidized natural gas equals 150 rials per kW/h. With costs being not actual, investment in the transformation of gas power plants into winds ones is not economical. One of the important items in the economic view is that it is costly and expensive to supply electricity through distribution networks to distant areas. Islands and coastal areas that are far from the main network and are capable of proper wind speed, use of wind turbines as mechanical simulators of electrical generators has significant attention. Impermanent nature and versatile speed of wind create changes in the output power of the generator. So this issue hardens the application of this system for consumers. In fact the purpose of this study is how to introduce a new controller for wind turbine aiming at improving quantity and quality of production power?

Importance of study

Shifts and sometimes intense frequencies of wind always create critical conditions in the rotation of wind turbine rotors which necessities the existence of a controlling and protection system within wind turbines. This controlling consists of high speeds due to not preparing a range of generator performance and also prevents from probable amortization or failure of the rotor. This part focuses on investigating such braking systems of wind turbines. Those turbines with variable angle impellers benefit from this system. The angle pitch of the impeller is almost zero at low and medium wind speeds. By increasing wind speed (higher than the speed of the turbine’s optimal performance) controlling mechanism leads to increasing in angle pitch and decreasing of estimation power coefficient so torque will be the result. Although this system is complicated because of having a mechanism to rotate impellers, it has also some advantages. When the power of the output system increases, this system orders impellers of the turbine to remove their slope to the wind. It is obvious that by reducing wind speed, these impellers return to the proper slope. This system ordered by a hydraulic mechanism [2].

Research purposes

Major purpose: Introducing a new controller for wind turbines aiming at improving quantity and quality of productivity power.

Minor purposes:

• Recognizing active static controlling system of wind turbines with quantity and quality of productivity power.

• Recognizing communications system and controlling quality of productivity power.

• Recognizing protective structures of wind turbines aiming at quantity and quality of productivity power.

• Recognizing wind transformer systems into electrical energy and wind turbines with quality of productivity power.

This is an applied study with a descriptive and survey method in collecting data. Descriptive due to image presented from status quo and survey because of collecting data through sampling from society and it is correlational regarding relationships between variables. The first collected data must be reviewed, manuscripts, audio files and observations are integrated. Then close opinions codified and data organized under these codes. Answers to each question categorized into several groups and to select performance type first collected data must be reviewed manuscripts, audio files and observations are integrated. Then close opinions codified and data organized under these codes. Answers to each question categorized into several groups.

Data collecting instruments

Library research method used in compilation of this study to collect related data to statistical sample in correlation stage.

Keypour and his colleagues investigated the effects of using wind turbines on quality of electricity network, increasing expansion of producing electricity utilizing wind energy during recent decades on one hand and effect of normal and transient behavior of these units on electricity network on another hand, clarify necessity to study quality of produced electricity in proper designation and improvement of such systems in various conditions. Hence, correct modeling and studying the electricity quality of these systems and introducing methods to reduce their destructive effects is necessary. Versatile speed wind turbines along with Doubly Fed Induction Generator (DFIG) simulated in the form of a production unit of electrical energy and parameters of electricity quality such as harmonic and flicker which are created due to electronic instruments and wind confusions respectively have been analyzed in this study.

Beheshtini and his colleagues have determined the optimal designation of wind turbines aiming at maximizing the output power of wind farms and minimizing the cost of turbines connection. Energy out of the wind is among important energy resources during recent years which has gained considerable attention in advanced countries. Wind energy is so cheap, clean, valuable and permanent. How to arrange and install turbines in farms needs accurate calculations regarding land and capital limitations to have the utmost energy from the power plants. This study has investigated how to arrange turbines on a wind farm to achieve a maximum power of farm and minimizing the cost of wiring between turbines at the same time. Considering wake equations, the effects of turbines on each other is also investigated. To solve the problem a new genetic algorithm represented. To study the represented algorithm’s performance, the results of this algorithm have been compared with a normal genetic algorithm and several basic answers. Results are demonstrative of better performance of the represented genetic algorithm.

Khosravi and his colleagues studied the state of wind energy in Khuzestan province to use wind turbines. Using wind turbines as an electrical energy generator within windy areas of different countries has changed into a commercial and inevitable process. So this study aimed at investigating the state of wind energy to extract energy through the installation of wind turbines in Khuzestan province. The methodology based on using meteorological station data in Khuzestan and calculating energy resultant from wind considering the installation of commercial wind turbines. 3-hour data of speed and wind direction within the common statistical course for selected stations of the province including stations of Bastan, Dezfoul, Behbahan, Abadan, Masjed Soleyman and Ahwaz obtained from Khuzestan meteorological office. Separate data of wind substituted by Weibull distribution function. Annual wind power density and other wind analogs obtained in altitudes of 10, 20 and 50 meters, One seventh power law model used to estimate wind speed in height above 10 meters. Results show that in Khuzestan province, stations of Dezfoul, Ahwaz and Abadan with 824 kw, 232 kw and 225 kw power, are suitable for installation and setting up turbines in wind commercial farms. According to the installation of wind commercial turbines in 50 meters height and rotor level of 80 meters and also considering the most power coefficient, productivity power of turbine energy, electrical energy, Dezfoul, Ahwaz and Abadan stations with 443 kW/s, 125 kW/s and 121 kW/s are suitable for installation of wind commercial turbines, respectively.

Khalouzade and his colleagues in nonlinear modeling of Dizbad wind turbine and its controlling based on random optimal feedback controller study, first modeling of wind turbine, induction generator, transitional shaft, static capacitor of reactive power and modeling transmission lines to nonlinearly control output of machine have been conducted which made up equations of nonlinear state space with 13 state variables. Considering not availability of states, process noise and also since wind quasi-random factor considered as the main generator of wind power plants and random component is one of comprising components of wind, it seemed suitable to use random controlling theory. So to control machine output, a random optimal estimator and a random optimal controller according to cost function designed for wind turbo generator system whose performance generalized to output feedback controller and also to state feedback controller through Kalman estimator and compared as state estimator. Reply of the closed-loop system with random optimal control has desired attenuation against wind fluctuations than Kalman estimator with pole placement which is demonstrative of the high efficiency of the random optimal controller.

Controlling wind turbine

Controlling slope of wind turbines: The controlling system of turbine peak checks turbine output each second. When the power of the output system increases, this system orders impellers of the turbine to remove their slope to the wind. It is obvious that by reducing wind speed, these impellers return to the proper slope. This system ordered by a hydraulic mechanism.

Static control system of wind turbine: In this system rotor impellers fixed at a particular angle and don’t rotate. This necessitates a hydraulic system that produces many problems since it must be fully involved with the aerodynamic mechanism of the turbine. Many existing turbines in the world use a static control system.

Active static control system of wind turbines: Big systems (IMW) use active control mechanisms. This method is similar to the slope control method. To achieve more torque powerless wind used and to achieve necessary energy low-speed winds are needed.

Whenever a machine obtained full power, you may notice an important difference in slope control systems: If generator overloaded, the machine rotates impellers slope opposite of determined direction by the slope control system. In other words, increasing the attach angle of the rotor’s impellers intensifies and deepens the statics, so wind energy wastes. Another advantage of static active control is that it controls output power better and more accurate than inactive static control, also prevents fluctuations of determined power of a thunderstorm.

Another advantage is that it performs pre-determinately in all highspeed winds. The output energy of the wind system reduces since rotates its impellers for more statics. The slope mechanism is usually ordered by hydraulics and stepper motor [3].

Control and order system

A part of the power plant considers all missions of the power plant and different factors such as speed and direction of the wind, speed of shaft, voltage and outpour frequency. Oil pressure and etc. and based on conditions, sends orders to actors. PLC is the main controller of most wind power plants.

Electrical distributing system

The electrical distribution system of wind power plants is a combination of minor low and medium voltage systems. The low voltage system has 480 V and contains ground wires related to turbines and transformers. Installed transformer increases low voltage to medium voltage of 5 kV and 34 kV and includes a key with 600 V secondary protection, transformer of three increasing phases and connect/disconnect key. Wind turbines can produce real energy which is useful for increasing transportation efficiency and voltage confirmation. The nature of what is distributed through wind makes generators closer to consuming centers and removes losses of energy transportation [4].

Transformers size determined by group arrangement of turbines. Medium voltage wires established inside the ground for a group of transformers and have junctions to airlines. Transportation basis has three-phase key installed in the upper part of protective lightning arrester (capable of being turned off from bottom), junctions of insulated wires, connection conductor or disconnected wires (wires covering). Mentioned transportation wires connect within the former position of wind power plant that is the point in which voltage increased to for transportation to network. All equipment, wires, wind turbines and bases contain a grid metal network connected to the ground. The mentioned ground connection system easily transfer step and touch voltage, extra voltages and lightning impulses.

Communications and control system: Each turbo generator consists of an electronic relationship that shows turbine behavior repeatedly. This system uses professional software and hardware and contains SCADA electrical system. Wind power plants protected through new relational wires, existing telephone informational networks and distant control.

Electronic system demonstrative for each camera will connect to communications box or sign at the bottom of the tower, communicational junctions locate near to accumulated airlines from this point, air and ground lines guide these lines through the small communicational building for sending through telephone lines to productivity center. So operators will be able to control and optimize turbines behavior simultaneously [5].

Retaining structures of wind turbines

Retaining structure of wind turbines used to retain generator and rotating parts or impellers if wind turbines. Wind turbines categorized into two groups of small and big units regarding the amount of produced electricity and considering needed power have different impellers lengths and heights.

Small wind turbines: These units used for productivity power of 50 kV to 100 kV. The height of these structures is between 9 m to 18 m selected based on the diameter and weight of the turbine and generator collection. The structure of these turbines is from freestanding metal, concrete or inhibitory type (Table 1).

Big wind turbines: These units used for more than 100 kV productivity power. Eight of the structure is more than 20 m and they are planned for more rapid wind speeds. The approximate weight of the turbine and its accessories is between. For instance one of the products of Vestas company named V80-2/0 mw is as follows:

| Length of rotating part | 60 m | 67 m | 78 m |

| Tower | 140 t/124 t | 158 t/142 t | 203 t/199 t |

| Capsule | 61 t | 61 t | 61 t |

| Rotor | 37 t | 37 t | 37 t |

| Total weight | 238 t/22 t | 256 t/240 t | 301 t/297 t |

Table 1. Productivity power of unit.

Conic metal or concrete structures used to retain these turbines. Retaining structure and also foundation made up construction parts of a project. In this study, the first different types of common structures for retaining wind turbines are introduced and then according to loads, technical characteristics of these structures will be investigated.

Retaining structure of wind turbine: Structures of wind turbines used to retain generator and rotating parts or impellers of wind turbine and grouped into freestanding and inhibitory structures.

Freestanding structures: These structures manufactured in different types and with different hardness and regarding material categorized into two groups of steel and concrete.

Metal structures used for both big and small units and have two types:

• Made of metal sheath.

• Concrete structures used for some of big turbines and are more

economical for large scale projects.

• Truss structure.

• Inhibitory structures, in these structures powers applied to main

basis transfers into several inhibition.

Performance of each structure differs in statics, economic issues and availability of materials are also determinant factors for selection in different types of towers. The useful life of every structure should be equal with or a little more than the useful life of the turbine.

Metal structures are manufactured in every height and resistance. The type of consumed concrete, construction method and concreting regarding the location of area are important for concrete structures. Generally, metal materials are more commonly used and concrete materials mostly used for big units [6].

Bases should fulfill the following needs:

• Loading and optimal confidence coefficients

• Resistance against environmental elements and their resultant

failure

• Geometrical and topographical issue of the area

• Aesthetic issues

Now a summary of each type of mentioned structures are presented here:

Truss structures: In members of the grid truss structure, pivotal force in forms of pressure or tensile created. But there will be a slight curve due to the weight of the structure, which is negligible. In constructing of truss structure for wind turbines, galvanized steel is usually used which is resistant against rustiness and corrosion.

Truss structures occupy more areas on the ground than structures made up of metal sheets with circular profiles, but it is unimportant since wind turbines established far from cities.

Metal sheath structures: The retaining structure of a wind turbine is possibly made like an empty piece with a variable or constant circular profile. Metal sheets can attach through welding or go into each other through telescopic connection so that the tower is made up of pieces that are connected. Sheath structure also needs other accessories for installation and permanent productivity such as proper appendices for installing ladder, safety cage, etc. Foundation connected by screws. Therefore, the structure is connected to the foundation by the surface of the pillar bottom and inhibitory bars [7].

Remote control systems in wind turbines

Shifts and sometimes intense frequencies of wind always create critical conditions in the rotation of wind turbine rotors which necessities the existence of a controlling and protection system within wind turbines. This controlling consists of high speeds due to not preparing a range of generator performance and also prevents from probable amortization or failure of the rotor. This part focuses on investigating such braking systems of wind turbines.

Considering wind turbines and their comprising systems, basically (control) plays a key role. One of these controls is remote controlling and power of wind turbine which is applied through one of the following elements:

• Controlling through loading.

• Controlling through impeller (air brake).

• Controlling emergencies through mechanical brakes.

In a and b states, controlling is continuous. But these are air and mechanical brakes used as wind turbines and control rotational speed which as a result power of wind turbine increases as mentioned below.

Controlling through impeller (air brake): Using the air brake system is one of the remote controlling methods of the turbine. In air brake with controlling through the impeller, this part only focuses on investigating this system within horizontal axis turbines.

Horizontal axis turbines: Generally in these kinds of turbines, impeller angle is variable or stable. If impeller angle is variable, turbine will be controlled remotely as:

• Controlling through changing pitch angle

• Controlling through stall creating system

But if impeller be stable, controlling will be performed through prearranged stall. Performance of each system is explained as follow:

Controlling through changing pitch angle: Those turbines with variable angle impellers benefit from this system. The angle pitch of the impeller is almost zero at low and medium wind speeds. By increasing wind speed (higher than the speed of the turbine’s optimal performance) controlling mechanism leads to increasing in angle pitch and decreasing of estimation power coefficient so torque will be the result. Although this system is complicated because of having a mechanism to rotate impellers, it has also some advantages like:

• Good power controlling

• Proper aerodynamic attenuation (due to absence of frequencies)

• Rapid reduction of load

• Implementing low power during turbine stability

• Easy to set up

• Self-braking

Helping stall creation: In this system, impellers rotate around their longitudinal axis. In these turbines, the impeller located in a proper pitch angle in the low and medium speed of the wind. To avoid ultra-speed state, impellers turn and through increasing drag force, the stall will be created [8].

Among advantages of this system are:

• Good power control

• Low loads while turbine is in synchronous state

• Easy to set up

• Self-braking

But besides complexity and cost, this system increases loads due to wind speed increase and creates frequency as a result of stall emergence.

Regulated stall: In such a system, the turbine impellers don’t move around the longitudinal axis, in other words, the impeller turbine is stable. The length of the impeller axis is arranged to increase the speed with two attack angles due to the increase of the rotor’s circular speed and to change lift and drag coefficient to fix speed remotely in torsion and thickness of different sections of the impeller. Stall state in impellers with less torsion across system makes controlling the speed of wind turbines so economical and easy, but has also some disadvantages:

• Energy losses

• Reduction of aerodynamic attenuation (due to stall and

frequencies)

• Implementation of much pressure during stability

• More difficult setting up

• Extra motor system need (for ultra-fast states)

Remote control system built from impeller control type usually built in big turbines (with power more than 300 kV).

Electronic transformers

Wind turbines with variable speed need one of DC/AC transformers (rectifier) and AC/DC (Cycloeonverter) to create synchronous power depend on the type of generator. Recently, the cost of electronic transformers diminished and their reliability significantly improved, these transformers use ATO elements, bipolar transistors, field-effect and recently GBT in high frequencies and medium and low powers and use transistors in high powers. First group elements can be connected or disconnected by gate signal while thyristors are only connected by implementing gate signal and extra transformers (commutation orbits) are needed for them to be turned off which has side effects [9].

DC/AC transformers

Inventors of semi-conductor commutation elements are categorized into three groups of compensatory natural (line) and spontaneous commutation. The inventor of natural commutation is cheaper than other convertors but it can only be connected to the network. Keys of commutation act through three-phase output voltage, so it cannot be used for supplying independent loads. Compulsory commutation inventor can supply independent load and network but instead, it is more expensive and less reliable due to the commutation axis.

Convertor with spontaneous commutation, commutation action performed by a capacitor and an extra transistor or semi-conductor elements can be disconnected. Spontaneous commutation inventors have three types of Current Source Inventor (CSI), Voltage Source Inventor (VSI) and Pulse Width Modulation (PWM).

In VSI, DS is the voltage source input and voltage output is squared or quasi-squared. In CSI, DS is the voltage source input and voltage output is squared reference stream or quasi-squared. In fact, VSI is dual of CSI and the output current-voltage of one of them is similar to the current and output voltage of another one.

The following figure shows a three-phase current source inventor which supplies a synchronous motor. In this axis, transistors 1, 6, 2, 4, 3 and 5 fired respectively and each transistor connected for 120°and disconnected for the next 240°, capacitors C1 and C4 perform commutation of transistors [10].

Input of inventor is the constant current Is.

Gate signals perform transistors guidance intervals and inventor output currents.

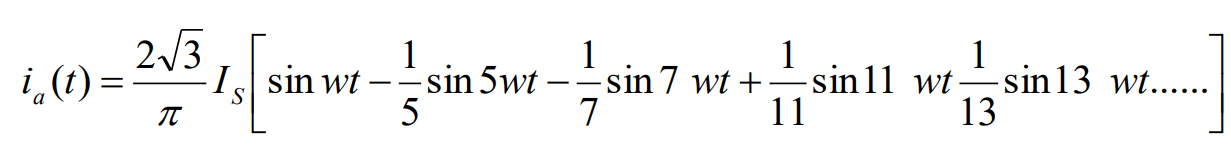

Three phase inventor to supply synchronous motor: In the same figure there are also transistors gate signals and currents of three phase out put transformer. Through combination of current phase a will be obtained.

Therefore, size of first harmonics of current phase a is:

and its effective amount is:

or 0.712. To supply independent loads or during synchronization with network, inventor output voltage must be controlled.

Output voltage of VSI (output current CSI) is controlled by changing pulse width of half voltage cycle (current). PWM sine is among common ways to control it. The main advantage of this method is less resultant output harmonics. In this method, gate signal is made through a train of triangular wave with sine signal.

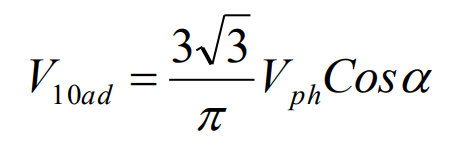

AC/DC transformers: The following figure shows the rectifier of the whole wave with diode elements. This transformer is investigated during two stages. During the first stage which half-cycle took place, within each 60° voltage of each phase applies to load repeatedly and during the second stage (next to half cycle) within each 60° voltage of each phase with reverse polarization applied to load repeatedly [11].

In part B of the same figure, the load voltage (transformer output) is illustrated. The output voltage is not perfectly DC and contains repels. The first harmonics of this voltage has 300 Hz frequencies. To reduce voltage appeal, a low pass filter must be used in output. If the transistor is used instead of the diode in the axis of the above figure, it will be possible to control the size of DC output voltage through modification of the transistors fire angle. If a, be the fire delay angle, size of output medium voltage will be:

So vph is the voltage of input phase.

It is possible to transform the variable frequency of speed generators output through the connection of an AC/DC transformer to a DC/AC one. Generally, the AC/DC transformer is a rectifier diode that its output filtered by the big inductor and also DC/AC transformer is a compulsory commutation CSI besides controlling PWM.

Despite VSI, CSI besides transferred active power control has also two advantages. First, it is possible to filter injected flows to load through the installation of the capacitor in transformer output and second is that there is no need for DC increasing transformer (cutter).

Electric transformers of wind turbine in stable speed

In this part, electric transformers of stable speed analyzed in two states of connection to power network and independent loading supply. And in the second state, methods of frequency confirmation and transformer output voltage explained by the change in wind speed and change in load [12].

Connection of wind power plants to global network

Production size or capacity of a wind turbine during a particular installation state depends on power and win conditions within an area. It is impossible to imagine that load supplies all necessary energy economically. As a rule, a wind system should be designed to supply 25% to 75% of total energy. Most of the residential consumptions need a machine capable of 1 kW to 10 kW capacity or more. Agricultural consumptions need 10 kW to 50 kW and commercial and small industries consumptions need 20 kW or more power. Since most of the buildings connected to the single supply line, many wind turbines owners have admitted to connecting their systems. These systems use the abovementioned supply line as a supporting system. Surplus electricity out of the turbine automatically enters the supply line and so supporting electricity provided. However, this amount doesn’t comprise real savings. Hence this amount determines demanded electricity based on time and size. Agreement of supply company for the lining is a long and complicated process that needs precise planning, communicating such a relationship must be investigated at the beginning of the research process about a wind system.

Changes in the consumption of energy systems and the cost of a wind system should be regarded while selecting a system. For example, a user with disordered consumption should select a turbine with a different size and performance which relatively demands constant consumption. Regarding the former, the size of the wind turbine should be a function of the demanded energy average during the requested period [13].

Disconnected systems to global network: Power systems out of the global network (separated or disconnected to the network) may lead to more costs. But high expenses of transportation of a power line to a distant location make such network-independent energy systems the most economical choice for distant houses or equipment. If the average wind speed is more than 12 m per hour in an area, a wind turbine will provide the cheapest form of energy in that area.

Since wind is an alternative phenomenon, these wind systems used as in the combination with batteries or other energy systems such as gas generators or solar electric panels to create a hybrid system (combined or mixed). Whenever demanded energy is more than the amount supplied by the turbine, batteries can provide necessary saved energy as a source of power. Supplied energy by batteries is only useful during somehow acute situations, but when there is the demand for a higher capacity of energy saving, a supporting system like diesel or benzene portable generator will be needed.

Planning out of global network systems: Determining the size of systems located in distant areas is fundamentally different from determining the size of a wind system for inter-network supply (supply of a global network) since remote control systems should be designed to supply the total demand for electricity. Before determining the size of a remote control system component, the supply load of the site (where it should be supplied) has to be determined. That is identifying electricity demand quantity based on daily or seasonal consumption. The purpose is to compare the needed amount of energy during different times in a day or year to explain when this amount will be available for the wind system. After considering wind alternation it would be possible to consider savings in the form of battery regarding saved energy in it to be able to supply three days without wind. Supporting generators mostly regarded as complementary suppliers in remote electric systems. These supporters help supporting systems prevent increasing charges in the battery to supply big loads during the demand for high power and instant loads, so the lifespan of batteries will increase. Also, these supporters show more productivity than batteries when the system is located in a full load state. So generators are designed bigger than medium size to be able prevent from stability of loaded system and also minimize fuel consumption and charge batteries at the same time [14].

As mentioned earlier, wind turbines use two kinds of brakes. Ari and dynamic brakes (disc), commanding systems within these brakes are usually two separated systems, that is when two above mentioned brakes have a problem with commands of control axis, mechanical systems order to brake. Safe brake systems are used.

The main criteria to select electric transformers of wind turbines are firstly cost and secondly efficiency, weight, volume and amount of confusion in the network. Permanente magnetic generator with more poles or asynchronous generator is used in turbines with stable or variable speed and low power and in variable speed state, generator connects to an AC/DC/AC electronic transformer. In this state, the quality of output power completely depends on the transformer performance. So using rapid semi-conductor keys with low losses not only accurately confirms output frequency but also reduces voltage harmonics and output current.

Due to low efficiency and harmonics in output, electronic transformers are not used in higher powers, since turbines have usually constant speed and only asynchronous or synchronous generator are used regarding nominal; the power of the turbine. All European companies use powers less than 750 kW and asynchronous generators due to advantages like low cost, structure simplicity and low cost to retain [15].

In powers more than this amount, the synchronous generator is used more than asynchronous generator due to lower cost and more controllability capacity. But due to the possibility of accurate controlling and regulating output voltage in electric transformers and low cost of the control system and also higher efficiency of variable speed turbines, it has been predicted that through the aid of technology progressions of electric transformers, speed turbines substituted by stable speed turbines.

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

Journal of Electrical & Electronic Systems received 733 citations as per Google Scholar report