Review - (2022) Volume 11, Issue 3

Received: 21-Mar-2022, Manuscript No. jme-22-57044;

Editor assigned: 23-Mar-2022, Pre QC No. jme-22-57044 (PQ);

Reviewed: 06-Apr-2022, QC No. jme-22- 57044;

Revised: 11-Apr-2022, Manuscript No. jme-22-57044 (R);

Published:

18-Apr-2022

, DOI: 10.37421/jme.2022.11.620

Citation:

Guo, Amy XY, Chenbo Geng, Zhiming Lin and Shan Cecilia Cao. “A Review of Research Progress on ω-phase in Titanium Alloys” J Material Sci Eng 11(2022):620

Metastable β titanium alloys with twinning and/or martensite transformation have been exploited as biomedical and structural materials owing to their biocompatibility and excellent comprehensive mechanical properties. The dispersed ω phase is an important precipitation strengthening phase, which plays an important role in improving the strength of titanium alloys and assisting the transformation of α-phase. Therefore, the research of ω phase transitions in titanium alloys has become one of the hot topics for decades. In this work, the latest related research reports are reviewed, including ω phase transition mechanism, classification, and model evolution. The advantages and disadvantages of related models are compared and finally, some scientific issues are put forward.

Titanium alloy • ω-phase • Precipitation strengthening • Phase transformation • ω-assisted nucleation.

In recent years, metastable β titanium alloy and nearly metastable β-titanium alloy is widely used in aviation navigation and various industrial production as they have excellent performance (such as the resistance of corrosion, excellent specific strength, high plasticity, etc.) [1,2]. These two types of alloys usually contain Mo, V, Nb, W, Ta, Fe, Cr and other elements whose β-phases are stable, which can ensure that a single β-phase can be obtained at ambient temperature after solid solution quenching from the high temperature β-phase region [3,4]. However, when the alloy composition is near the critical concentration, the alloy will form ω-phases after high temperature quenching, which can make the strength and hardness of the alloy increase sharply, but the plasticity decreases dramatically. In addition, the alloy that contains more β-phase stable elements, although athermal ω-phase is formed during quenching, it is formed isothermal ω-phase during subsequent aging. Although the formation conditions and mechanisms of the two ω phases are different, they share the same properties and crystal structures [5,6]. Since American researchers Frost and Parris discovered ω-phase in Ti-Cr alloys and Ti-Mo alloys in 1954, material researchers have been carrying out meticulous research on ω-phase transition [7]. Therefore, the important progress of ω phase transition in titanium alloys and is summarized in this paper, which can help readers to understand the mechanism of ω phase transformation.

The formation of athermal ω-phase

Up till now, we can basically determine that the ω-phase can be divided into athermal ω-phase and isothermal ω-phase. This former one is formed during rapidly quenching from the β-phase region, while the latter one is produced through aging progress [8,9]. This is different from the traditional shear controlled martensitic phase transition, although the athermal β-ω phase transition is proved to be diffusion free by rapid cooling. The traditional martensitic transformation in titanium alloys is resulting from collective shear of atoms on the plane of the β phase, and structures formed have typical strip and sheet characteristics [10]. The formation of the athermal ω phase is usually caused by the collapse of the parent phase atoms on the {111} plane. In this model, De Fontaine and Cook et al. believe that the ω phase transition is the atom's moving edge perpendicular to the {111}β plane <111> direction perpendicular to {111}β plane, and the atomic movement produces local ordering [11]. De Fontaine's displacement wave formation process does not require nucleation in nature and requires little or no activation barrier, which on the surface is consistent with the fact that rapid quenching can lead to the formation of athermal ω phase. However, it does not actually conform to the structural characteristics of the athermal ω phase [11]. Experimental results have confirmed that the athermal ω phas e particles are only 2~10 nm, and there are obvious intervals between the particles [12]. For this reason, De Fontaine's displacement waves must end at the beginning to obtain an athermal ω phase morphology consistent with the experiment, but the control of this phase transition is difficult to achieve [11]. Cook then modulated the amplitude of De Fontaine's displacement wave and believed that the wave packet with regular distribution in space was unrelated to the discrete ω phase particles formed [11,12]. After such a treatment, it can be considered that once the ω-phase particles grow completely, their lattice no longer maintains these elastic waves, and the formation mechanism of the athermal ω-phase will become inef fective.

Since both martensitic and athermal ω transformations in titanium alloys are the result of non-diffusion free atomic shearing, there must be some intrinsic relationship between the two transformations [13,14]. However, although the displacement wave and amplitude modulation model can well explain the formation and microstructure characteristics of the athermal ω phase, the model does not fully explain the difference and relationship between the athermal ω phase and the martensitic transformation. A new model of athermal ω phase in titanium alloys was proposed by using binding energy [15]. According to the model, the formation of the athermal ω phase in titanium alloy is not related to the collapse of atoms on the {110} plane, but the collapse of atoms on the {110} plane of parent β phase along the direction of (111) into the {111} plane. In fact, the formation of the athermal ω phase is similar to the martensitic transformation in titanium alloys. They all start on the (110) plane of ω phase, but the resistance of athermal ω phase transformation is larger than that of martensite, which results as not all atoms can perform collective shear motion when the athermal ω-phase transformation, but only some atoms participate in this motion. These moving atoms can only travel along <111> direction collapses into the {111}β plane, where the energy of the plane is lower, forming the athermal ω phase. In the phase transformation process, the large phase transformation resistance and the inconsistent atomic motion inevitably leads to the difficulty of the growth of the athermal ω phase particles, which is also the reason why the microstructure morphology of the athermal ω phase often presents fine dispersion and there is obvious separation between the particle s.

The schematic diagram of the motion of atoms in the process of collapse is shown in Figure 1. In which the hollow circle "O" represents the atom that can form (0002) crystal plane in ω phase after collapse, and the solid circle "●" represents the atom that can form (0001) crystal plane in ω phase after collapse. Figure 1b shows the collapse result of hollow circle atom in Figure 1a, that is, the formation of (0002) crystal plane in ω phase. Figure 1c shows the collapse of solid circular atoms in Figure 1a, the formation of (0001) crystal planes in the ω phase. Figure 1d consists of a group l of (0002) crystal faces in Figure 1b and two groups of (0001) crystal face in Figure 1c.

Figure 1. (a) Formation model of athermal ω-phase: the atom movement pathways of β phase from the [110] plane to [111] plane; [b] The formed [0002] crystal plane in ω-phase; [c] The formed [0001] crystal plane in ω-phase; [d] the athermal ω-phase. (Reproduced with permission from[11]

The formation of isothermal ω-phase

When the content of β-stabilizing elements in metastable β-titanium alloys is high, a single β-phase is formed by quenching from the β-phase region, but no athermal ω-phase is formed. During the subsequent aging process, the metastable β phase may decompose into the ω phase, known as the isothermal ω phase [16-18].

The traditional view may be that isothermal omega phase is the phase transformation controlled by thermal activation energy diffusion mechanism, which should also be a nucleation growth process [19,20]. However, some phenomena conflict with the traditional nucleation and growth theory occurs during the formation of isothermal ω-phase. Duerig et al. have found that in Ti-10V-2Fe-3Al alloys, the growth rate of the isothermal ω phase remains high even at lower temperatures where diffusion can be prevented [12]. It is also found that aging temperature has a great effect on the size and dispersion of isothermal ω phase particles, while aging time has no obvious effect on them. Therefore, the formation of isothermal ω phase is not completely dominated by diffusion mechanism. F. Prima et al. also mentioned the result that the nucleation of isothermal omega phase in Ti-6.8Mo-4.5Fe-1.5Al alloy depends on the athermal ω-phase, and based on this, proposed the regulation method of ω phase volume fraction in β titanium alloy [21]. However, the mechanism of isothermal ω phase formation on a single β phase matrix in metastable β titanium alloys has not been unanimously recognized.

Devaraj [22] provided experimental evidence that the simultaneous instability of composition and structure in Ti-Mo alloy leads to the precipitation of ω particles from the β phase matrix by using quantitative modification of composition and high resolution scanning transmission electron (HRTEM) microscope. In Figure 2 the results show that the simultaneous instability of structure and composition leads to the formation of ω-like crystal embryos during the rapid cooling of the beta-phase region at high temperature. The phase separation transition also takes place during the formation of these ω-like phase embryos. Partial displacement collapse will occur on the {111}-plane of the β phase matrix in some regions with less Mo element. During subsequent isothermal tempering, these ω-like phase embryos grow and coarse, with further collapse of (111)-crystal planes of the β phase matrix and segregation of Mo element, resulting in isothermal ω phase formation. This model is also called displacement-diffusion mixed model [15].

Figure 2. Schematic illustrations of the transformation of ω phase: [a] β-phase; [b]ω1-phase; [c]ω2-phase (Reproduced with permission from[15]).

Recently, Jun-Heng Gao and Alexander J. Knowles [23] researched the air-cooled Ti-7Mo-3Cr-1Fe alloy modified the deformation mechanism from {332} twinning and dislocation slip, especially in the water quenched alloy, to localized dislocation plasticity in ω-void channels. Figure 3 shows the EBSD map of their STA sample.

Figure 3. EBSD map with IPF color coding of [a] β-phase and [b] α-phase of the Ti-12Mo STA sample. [c]Stereographic projections of bcc [110] planes and [111] directions, hcp [0001] basal plane and [2110] directions, for two selected β matrix/α precipitates/β twin interfaces. Colors represent the IPF color of the corresponding orientation in the EBSD map. (Reproduced with permission from[23]).

The formation of stress induced ω-phase

Metastable β titanium alloys can form stress induced ω phase during plastic deformation at room temperature [11,24,25]. Generally, the morphology of the stress induced phase is disk like, and the formation of the metastable phase is often achieved through mechanical twinning [24-26]. Hanada systematically investigated the relationship between {332}<113> mechanical twinning and stress induced ω transformation in Ti-(16-22)V alloys [11]. In addition, Sun et al. indicates that the effect of phase stability on stress induced ω phase transition and {332}<113> effect of twin deformation is greater [24]. The results show that the mechanism of deformation is related to the content of ω phase stable element V in Ti-(16- 22)V binary alloy. When V content is 16 at.%, the deformation of the alloy is realized by stress induced ω phase transformation. When the content of V is 18 at.%, the plastic deformation of the alloy can be induced by stress induced ω phase transformation and {332} <113> beta deformation twinning is realized together; However, when the V content is 20 at.% ~22 at.%, the plastic deformation of the alloy is only {332}<113> beta-morphing twinning can be achieved. Wang et al. [25] investigated the effect of the non-metallic element O on the stress induced ω phase transition. The results show that higher O content can inhibit the stress induced ω phase transition in Ti-20V alloy. In addition, King et al. observed the stress induced ω phase transition and its accompanying {112}<111> in the deformed Ti-23Nb-0.7Ta-2Zr-1.2O alloy by HRTEM [22].

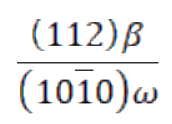

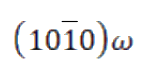

In Chen’s work [10], which is shown in Figure 4 the function determined by omega phase during the {112}<111>β twinning in Ti-Mo alloys were investigated under first principles calculations at atomic scale. In the energy favorable interface of

Figure 4. Successive slipping of partial dislocation on [a] (101 ̅0)ω and [c] {112}<111>β twinning nucleation following [b] the ω-assisted and [d] the conventional modes in Ti-Mo alloy with different Mo concentrations. (Reproduced with permission from [10]).

ω-phase assisted α-phase nucleation

At present, the mechanism of action of ω-phase particles in α-phase nucleation is still controversial [27-30]. This is mainly due to the fact that the decomposition mechanism of phase particles is not very unified and clear in the current academic circle, and the complex interface structure also affects the effect of ω-phase assisted α phase nucleation. In the system with a large mismatch between β phase and ω phase, phase nucleation generally occurs at the prominent position and dislocation on the ω/β interface [31]. The cubic ω phase particles will be coarsened during aging and lose coherence with the matrix β phase, which can provide potential nucleation sites for the precipitation of α phase. In the systems with low mismatch between ω and β (such as Ti-Mo), it is generally considered that the ω phase particles of sphere or ellipsoid cannot provide a good nucleation location for α phase precipitation. In Ti-15%Mo [32] and Ti-15V3Cr-3Sn-3Al [33], the effect of ω phase assisting α phase particle nucleation can also be obtained through special processing (such as two step aging). Furthermore, 3D atomic probe results further indicate that ω phase particles in low ω/β interface systems can be enriched away from ω/β interface by emitting phase stable elements such as Al to assist α phase nucleation [32].

Shi and Zheng investigate the mechanisms of ω-assisted α nucleation for microstructure refinement in Ti-20V alloy, which is metastable β titanium [34]. They also quantitatively analyzed the individual and combined effects of concentration and stress fields associated with a growing isothermal ω phase rash, and the potency of the ω/β interface on the activation energy barrier for α nucleation as a function of ω precipitation size and coherence state. They also delivered interplay among these three factors which determines the most potent ω particle size for inducing α nucleation and the most favorable nucleation site, as shown in Figure 5.

Figure 5. Elastic interaction energy, Eint, associated with an α nucleus around a coherent pre-existing ω particle with different size and morphology (cuboidal vs. ellipsoidal). The size along <111>β of the ω particles in [a], [c] and [e] are approximately 50, 25 and 30 nm, respectively. The variation of Eint around the ω precipitate is shown on the (010)β cross-section through the center of the ω precipitate. The isoenergy surface in purple in [b], [d] and [f] corresponds to Eint=−1250 J/mol. For cuboidal ω particle, the isosurface also indicates the most favorable nucleation site for the α phase, i.e. along the [010]β edge of the pre-existing ω precipitates (Reproduced with permission from[32]).

ω-embrittlement in metastable β-titanium Alloys

ω-embrittlement is common in metastable beta-titanium alloys, while the fundamental understanding on the damage fracture mechanism remains disputable. Chen et al. used the ω-brittleness of Ti-10Cr (wt.%) gold with high misfit was systematically studied by coupling experiments and first principles calculations [35].

The results show that brittle cleavage fracture exists in tensile specimens regardless of quenching state or subsequent aging state. Microcosmic nucleation and propagation of cracks occur along slip bands, in which first disordered ω-lattice and then local (β+ω) amorphous structures develop in the shape of white patches. The mechanically driven local amorphous mechanism is due to the covalent properties of ω-precipitated atomic bonds due to the composition distribution of Cr. ω-precipitated phase has a very high energy barrier, which resists dislocation sliding and causes dislocation to stack up in front of the precipitated ω-phase, resulting in their lattice disorder. These findings provide new insights into the damage and fracture behavior of highly mismatched β-titanium alloys such as Ti-Cr alloys, as shown in Figure 6.

Figure 6. TEM characterization of deformation microstructure in the Ti-10Cr ST sample: [a] the overall SEM deformation surface showing two locations for preparing in-depth TEM foils by FIB. One TEM lamella is cut across the slip band, i.e., Region, and the other one is extracted from crack tip, i.e., Region. The inset presents an as-fabricated TEM foil; [b] the BF-TEM image of region taken along ½(011)β zone axis. The Slip step on the sample surface is marked by an arrow, and the slip band is locally enlarged as the inset; (c) the SAED pattern around the slip band in [b], as marked by a circle; [d] and [e] DF images taken from (0001)ω1 and (0001)ω2 reflections, respectively; [f] the HRTEM image of the slip band. The boundary is outlined by dashed lines. The inset is the corresponding FFT pattern, where the brilliant b-spots are circled, while the ill-defined spots are highlighted by arrows; [g] the other representative HRTEM inside the slip band. The bottom-left inset is overall morphology of slip band, and the center-right inset is the FFT pattern of the rectangle inside the band. (Reproduced with permission from[35]).

Effect of interstitial oxygen on ω precipitation of metastable β alloy

The formation and stability of stable ω and stable α phases during deformation have a direct effect on the aging behavior of metastable β titanium alloys [36-39]. Interstitial oxygen can lead to brittleness of titanium alloy, which affects phase stability and structural properties of the alloy. They relate to oxygen, which plays a key role in the development of ω and α precipitation distributions and associated mechanical properties, which is another example of how oxygen can be a useful alloying element in betatitanium alloys, as shown in Figure 7.

Figure 7. SEM-BSE images of (a) directly aged Ti-15Mo with 0.1 at% O and (b) oxidized and aged Ti-15Mo with 1.5 at% O aged for 24 h at 500°C. Insets show EBSD inverse pole figure maps with crystal grain orientations and the selected grain denoted by the black arrow with associated cubic lattice projection for microstructures in (a) and (b). (c) Bright-field TEM image of oxidized and aged Ti-15Mo aged for 24 h at 500°C with 1.5 at% O. Inset shows SAED pattern for the [110]β zone axis showing β and ω diffraction spots. (d) SEM-BSE image of oxidized and aged Ti-15Mo with 2.2 at % O aged for 24 h at 500°C (Reproduced with permission from [25])

The effect of high interspace oxygen content (2.6 at.% O) on the precipitation of aged Ti-15Mo ω and α and its effect on compressive mechanical properties is pointed out [25]:

1. The high oxygen level reduces the growth rate of ω precipitation, resulting in the transformation of ω morphology from random ellipse without O to cuboid shape. After aging at 400oC and 500oC, O and Ti are distributed to ω and Mo to β. After 500°C isothermal aging, α precipitation has the highest oxygen content of 2.2 at.% O except for ω formation.

2. The influence of oxygen on the physical properties of omega groups can depend on the influence of oxygen on the ω form and the ω forms. The oxygen rich precipitation columns also have a greater stress density than the oxygen free ones, and instead they notice various ω cutouts, permeable metastable, and mutations. Increased strength is determined by precipitation under the influence of oxygen.

3. After aging at 600°C, the high oxygen content induced a finer α precipitation size and a higher quantitative density than the anaerobic sample. This refinement is related to the increased nucleation power α precipitation with high oxygen content, which leads to faster nucleation of fine shales. Oxygen induced refinement in is combined with the ω-assisted nucleation mechanism to obtain smaller α precipitation size.

4. During microcolumn compression, the refined α phase obtained by increasing oxygen concentration and two step aging has smaller size effect and higher compensative yield strength.

Strengthening effect of ω phase in titanium Alloys

ω-phase can sharply increase alloy’s yield strength, and there are several ways to restrengthen alloys by forming ω-precipitate. Figure 8 explains how the ω phase plane strengthens the alloy [40]. For example, adjusting the composition of alloy can significantly enhance their performance. Such as Ti-12Mo, Ti-9Mo-6W [10], Ti-10Cr and Ti-7Mo-3Cr [15]. Alexander et al. found that the ω phase growth of air-cooled Ti-7Mo-3Cr-1Fe alloy is obvious in microstructure analysis [41]. Their paper provides a new method for developing ω phase strengthening of metastable β titanium alloys. The addition of (1wt.%) Fe specially designed Ti-7Mo-3Cr alloy can effectively control the growth of ω phase after air cooling, thus achieving ultra-high yield strength (1210 MPa) and large ductility (0.15). The microstructure analysis of the deformed Ti-7Mo-3Cr-1Fe alloy shows that the growth of the ω-phase of the air-cooled Ti-7Mo-3Cr-1Fe alloy changes the deformation mechanism of the water quenched Ti-7Mo-3Cr-1Fe alloy sliding from {332} twins and dislocation to local dislocation plasticity in the ω-channel.

Figure 8. A schematic diagram showing the various mechanisms by which samples A and B show different ω-phase formation propensity. (Reproduced with permission from [40])

Although ω phases have been found in titanium alloys for several decades, ω phase transitions and their effects on the microstructure and properties of alloys are still poorly understood. There are still differences on fatal issues such as the formation and decomposition mechanism of ω phase. In recent years, the study of ω-assisted α nucleation has become one of the hot issues in the field of titanium alloys. However, the stability regulation of ω-assisted α nucleation is still facing many difficulties and is still in the experimental research stage. With the development of researching technologies, such as the widespread utility of high throughput experiments and introduction of artificial intelligence in material research, it is do believe that unsolved problems of ω phase will lift the veil of mystery and then Promote the development of materials science.

Acknowledgments

The authors would like to appreciate the financial and technical support received from the Shanghai University of Materials Genome Institute (MGI).

S. C. Cao and A. Guo designed the study. A. Guo and C. Geng wrote the main draft of the paper. Z. Lin organized Figures.

The authors declare no conflict of interest.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

[Cross ref] [Research Gate] [J-Global]

[Cross ref] [Research Gate] [Pub Med]

[Cross ref] [Research Gate] [Scinapse]

[Cross ref] [Research Gate] [Springer]

Journal of Material Sciences & Engineering received 3677 citations as per Google Scholar report