Research - (2020) Volume 10, Issue 3

Received: 20-May-2020

Published:

12-Jun-2020

, DOI: 10.37421/jcde.2020.10.347

Citation: Oyaro Damaris Kerubo, Zablon Isaboke Oonge and Patts Meshack Odira. “Anaerobic Digestion of Banana Wastes†Civil Environ Eng 10 (2020): 347 doi: 10.37421/jcde.2020.10.347

Copyright: © 2020 Oyaro DK, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Agriculture is one of the main economic activities for Kenyans; the wastes from agriculture are minimally used. Among the crops grown in Kenya is the banana and produces about one million tonnes of bananas yearly, mostly for local consumption, of which the banana herb produces the fruits once in a lifetime, thus the stem becomes waste afterward. The waste from the banana plant includes leaves, stems, peduncles, peels, and rejected fruits. The banana waste is organic and thus is suitable for anaerobic digestion in which the solid digestate has suitable nutrients to be used as fertilizer. Batch fermentation at the mesophilic temperature range was carried out in triple determinations, this also applied to the blank sample. After the batch test was complete, the pH of the fermentation residue was measured electrochemically using a pH meter. The COD of the residue (both Solid and liquid) was also determined. Analysis of the biogas produced by gas chromatography enabled the methane part of the gas to be calculated.

Biogas • Batch test • Agricultural wastes • Digestate • Methane

Kenya faces problems of both the commercial energy forms that have fuelled economic development and the traditional energy sources upon which most of the population still depend for survival. The traditional sources of fuel are not energy sufficient and emit harmful emissions especially carbon monoxide that has led to many deaths in both rural and urban areas. Overreliance on primary biomass energy has led to the widespread exploitation of forest resources with adverse environmental impacts. Forest cover, that once acted as the water catchment area has diminished with time; substantially below the minimum recommended coverage of 10%. As a result, a reduced amount of natural water resources, rivers have decreased in size or even dried up, reduced rainfall, and the dam water levels have gone down leading to less hydropower generation, thus, inconsistent power supply and frequent power outages. Kenya depends mostly on hydropower, these calls for exploitation of other sources of power to supplement it. The use of petroleum for power generation does not offer a lasting solution due to fluctuations in global market prices of crude oil, and the climate impacts of increased greenhouse gasses emissions. Fossil fuels are also, not renewable are diminishing in availability and may cost heavily on foreign exchange in the future. Embracing the use of Agricultural wastes (banana waste included) will provide a solution to mitigate some of the environmental, health and energy problems in Kenya especially the rural areas and also attain benefits such as quality fertilizer for good farming practices, and above all good banana waste management would have been achieved.

Agriculture is one of the leading economic activities in Kenya with almost 75% of the population making their living from it. Most farmers other than growing cash crops grow food crops for their consumption, among the food crops grown in Kenya are the bananas. Banana occupies a distinctive place in Kenya’s national as well as the household economy. It occupies only 7.44% of the gross cropped area, but its share in total fruit area of Kenya is quite substantial at 55%. Nutritionally, banana is superior to many other fruits. In several provinces of Kenya, large proportions of the farmers grow and consume bananas as one of the staple foods. Nearly 83.5% of the total banana output comes from small-scale farmers owning up to 0.5 hectares of land [1].

After harvest there are the agricultural wastes, which are the residues left behind after harvesting the food part of the crop, they include stalks, stems, roots, leaves, cobs, and straws. The common practice of handling these wastes is burning them before planting again new crops, feeding to livestock, or leaving them on the land, thus, converting these wastes to biofuels will assist in environmental protection and proper waste management. The four main marketing channels that carry banana products from the farm gate to the ultimate consumer:

• A simple channel in which banana moves from a small farm to rural retailers and ultimately to the rural consumer.

• Produce goes to a village or other assembler and then to the wholesale market for onward transmission to urban retailers.

• Produce from a relatively large-scale producer goes directly to wholesale markets and then to the retailers in the urban areas.

• The bananas are imported (from Uganda or Tanzania). From the wholesale market, the bananas go to the consumer through open-air retail markets, kiosks, high-end greengrocers, or supermarkets.

• With the recent introduction of banana processing factories in some parts of Kenya, some of the banana produce is taken to the factories for processing.

From this marketing chain there varied wastes generated and since bananas when ripe are highly perishable mostly banana leaves are used to protect the banana fruit.

The potential for methane production depends on the status, type, and constituents of the organic materials undergoing fermentation and these affect the quality of biogas [2]. Banana waste which consists of waste or rejected bananas, Pseudo stem, peels, leaves, and peduncle: each part has its biogas production potential and quality. From various literatures banana waste can be better managed by turning it to biomass feedstock, Owing to its organic nature.

• Amount of residue (tons per year)

• Seasonal availability of the residue (for biogas production a residue

should be available during the whole year or should be storable)

• Dry matter (DM) Content of the residue (% fresh matter, FM)

• Volatile solids (VS) content (% DM)

• Biogas potential for the substrate (m3/t VS)

• Methane content in the biogas (%) [3]

Substrates and inoculum (seeding sludge)

The substrates used in this study were banana leaf (midrib and leaf blade), banana stem (leaf sheath), and banana peduncle. The seeding sludge (inoculum) was untreated digested sludge in as per DIN 38414-8 more than a week before the experiment. The seeding sludge was stored at 37°C in such a way that the sludge reduced most of its gas production and to deplete the residual biodegradable organic material present in it.

The parameters used for characterizing substrates for fermentation are derived from their biotechnological suitability, the preparatory work required, and from the suitability-either from a legal point of view or as related to waste disposal legislation of the substrate for fermentation. Another important characterization is the chemical composition of the substrate, from this we can already conclude not only fermentability but also the gas yield to be expected. From the legal classification of the substrate, for example, waste, or as an animal by-product, characterization statuses such as hygiene status or utilization are derived [4].

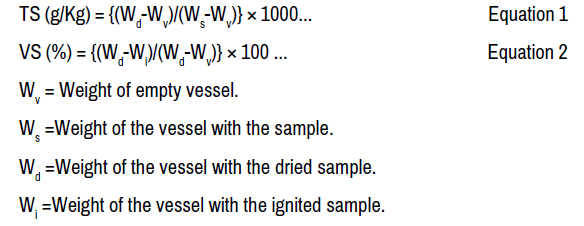

The characteristic parameters used in this study were, for the consistency, the substrates were all in solid-state. According to legal classification as defined by VDI-4630, the substrates were farmyard manure types. For the chemical composition, The Dry matter Total solids (TS) and the Volatile solids (VS) which are the same as the organic dry matter content (oDM) was determined. The solids content of the samples was determined according to the European standards (EN 12879 and EN 12880). For determining the total solids (TS), samples with certain volume or weight were placed in ceramic vessels and dried in a drying oven at 105 ± 2°C for 24 hours until constant weight. After cooling in the desiccators, the samples were weighed for TS measurement. The samples then ignited at 550°C for 2 hours in a furnace for Volatile solids (VS) determination. The VS was determined by subtraction of the minerals content of the sludge sample (residual ash after ignition) from the total solids content. The formulas for calculation of Total solids and Volatile solids were as shown by equations 1and 2.

The substrates were prepared for the batch test by shredding them into smaller sizes. This was done to provide a large surface area for adsorbing the substrate that would result in increased microbial activity and hence increased gas production. The leaf was prepared by using the ratio of 30% midrib to 70% leaf blade, for the midrib it was shredded to a size of less than 10mm but the leaf blade has already a high surface area due to its broad shape thus it was shredded to a size slightly larger than the midrib but enough to pass through the batch test bottle with ease. The stem and peduncle were shredded to particle sizes of less than 10 mm.

The fermentation test as per VDI-4630. Fermentation tests of this kind provide information regarding:

• Fundamental evaluation of biogas yields and the anaerobic degradability of a material or mixture of materials.

• Qualitative appraisal of the speed of degradation of a material under investigation.

• Qualitative evaluation of the inhibitory effect of the material under investigation in the range of concentrations in the test.

The fermentation batch-test does not provide information in regards to:-

• Process stability in reactors which are continuously fed with the material or mixture of materials under investigation.

• Biogas production under practical conditions due to possible negative and possible synergistic effects.

• Mono-fermentability of the substrate under process conditions.

• The limits of organic loading rate per unit volume.

The sets criteria to be followed to achieve good results [4]. The criteria followed in this study were, Batch fermentation was carried out in triple determinations, this also applied to the blank sample. First the samples of leaves, peduncle, and Pseudo stem were cut into small pieces to have a high surface area for the substrate thus enhancing bacterial degradation. The required amount of each substrate was then weighed in triplicate and then put carefully to the fermentation vessel. Then water was measured and fed into the fermentation vessels, then followed by the seeding sludge. The blank was fed with an equivalent amount of water instead of the substrate.

Before closing the fermentation vessels, the gas phase was flushed with nitrogen for 10 seconds to remove residual oxygen from the gas phase. The vessels were then immediately sealed and put into the fermentation chamber, which was set up at a temperature of 37°C and this was maintained throughout the experiment, thus the fermentation batch test was carried out at mesophilic temperatures.

The volume of the biogas produced was measured indirectly by a pressure measurement instrument. The gas pressures were then read off after every five minutes; this was automatically recorded. The test continued until the gas pressure changes reduced sufficiently to levels that showed there was very little or no further gas production. Thus, the fermentation batch test was on for 51 days.

The recorded gas pressures after the 51 days were then collected and analysed. Precaution taken care off in the running of the test was to ensure that the gas pressure in the fermentation vessel did not exceed 1.8 bars when this was reached the gas was released to avoid bottle breakage, the gas accumulated from dissolving into the sample mixture again and to some extent, influence on microbial growth.

After the batch test was complete, the pH of the fermentation residue was measured electrochemically using a pH meter. The COD of the residue (both Solid and liquid) was also determined. The gas produced was also subjected to further tests to determine the composition of the gas.

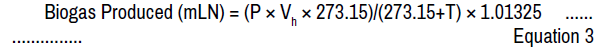

The calculations with regards to the anaerobic batch test, for the total volume of gas produced (Biogas), was calculated by the formula in equation 3.

P=Gas pressure in the reactor vessel in bars

T=Gas temperature in (°C)

Vh=Volume of headspace in the reactor

1.01325=Standard pressure in bars

273.15 = Conversion factor added to temperature in (°C) to convert to Kelvin 1.

Since the experiment was done in triplicates, the average values were then used for each substrate.

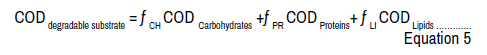

COD is calculated rather than measured due to the complexities involved measuring it. COD of a substrate can be calculated from the fraction of carbohydrates, proteins, and lipids in the substrate. For carbohydrates, the COD can calculate from the concentration of the oxidizable compound in the sample, based on its stoichiometric reaction with oxygen to yield CO2 (assume all C goes to CO2), H2O (assume all H goes to H2O), and NH3 (assume all N goes to NH3), using equation 15. Proteins have an average value of COD of 1.2 g Oxygen g-1 oDM while lipids the average value is 2.6 g Oxygen g-1 oDM [6].

![]()

C = Concentration of oxidizable compound in the sample.

FW = Formula weight of the oxidizable compound in the sample.

RMO = The Ratio of the number of moles of oxygen to the number of moles of oxidizable compound in their reaction to carbon dioxide, water, and ammonia.

Thus to get the COD of the substrate, Equation 4 is used.

fraction of carbohydrates

fraction of carbohydrates

fraction of Proteins

fraction of Proteins

fraction of lipids [6]

fraction of lipids [6]

Substrates used included:-

• Banana leaf (70% leaf blade and 30% midrib )

• Banana stem (leaf sheath)

• Banana peduncle. (floral Stalk)

Table 2 shows the composition of the wastes for COD calculations.

| COD Stem (g O2 g-1 oDM) | COD Leaf (g O2 g-1 oDM) | COD Peduncle (gO2 g-1 oDM) | |

|---|---|---|---|

| Lignin | 0.18 | 0.35 | 0.19 |

| Cellulose | 0.27 | 0.19 | 0.14 |

| Holocellulose | 0.35 | 0.33 | 0.19 |

| Pentosans | 0.06 | 0.07 | 0.05 |

| Starch | 0.07 | 0.01 | 0.28 |

| Proteins | 0.02 | 0.06 | 0.03 |

| Total COD | 0.95 | 1.01 | 0.89 |

Table 2. Chemical composition for COD calculations.

Lignin, cellulose, hollocellulose, pentosans, and starch are all carbohydrates. Their COD is calculated assuming the concentration of the oxidizable compound in the sample is 1gsubstance g-1oDM. Calculation of the various substrates COD using Equation 5 gives the results in Table 3.

| Stem (%) | Leaf (%) | Peduncle (%) | |

|---|---|---|---|

| Lignin (C9H10O2, C10H12O3, C11H14O4) | 9.37 | 18.27 | 9.70 |

| Cellulose (C6H6O5) | 26.27 | 18.70 | 14.23 |

| Holocellulose (C6H6O5) | 35.00 | 32.38 | 18.40 |

| Pentosans (C5H4O5) | 8.73 | 10.63 | 7.25 |

| Starch (C6H10O5) | 5.92 | 0.74 | 23.84 |

| Proteins | 1.34 | 5.28 | 2.90 |

Table 3. Calculated COD for the various substrates.

The COD for the seeding sludge used is 28,000 mg O2/l. For the batch test the COD values were as shown in Table 4. The COD for the liquid digestate after the batch test is as shown in Table 5.

| Component | COD Value |

|---|---|

| Stem | 47.5 (g/Kg) |

| Leaf | 236.9 (g/Kg) |

| Peduncle | 70.3 (g/Kg) |

| Seeding sludge | 7,000 mgO2/l |

Table 4. COD used in the batch test.

| Component | COD with inoculum (g/L) |

COD without inoculum (g/L) |

|---|---|---|

| Stem | 14.3 | - |

| Leaf | 23.2 | 3.9 |

| Peduncle | 21.5 | 2.2 |

| Seeding sludge | 19.3 | - |

Table 5. COD values after the batch test.

pH

The pH after the batch test was measured as shown in Table 6.

| Component | pH |

|---|---|

| Stem | 7.56 |

| Leaf | 7.58 |

| Peduncle | 7.64 |

| Seeding sludge | 7.84 |

Table 6. PH values after the batch test.

The microbial metabolism is influenced by pH variations in the digester. At a pH greater than 5 the efficiency is high methanogenesis proceeds only at a high rate when the pH is maintained in the neutral range. Most anaerobic bacteria including methane forming bacteria function in a pH range of 6.5 to 7.5, but optimally at a pH of 6.8 to 7.6, and the rate of methane production may decrease if the pH is lower than 6.3 or higher than 7.8 [7]. Thus the experiment took place in a suitable pH since all had a pH within the desired range.

Digestate use

Solid residue: The banana waste digestate has many highly desirable qualities as compost since it does not contain heavy metals contamination, plastic, or glasses. The pH as shown in Table 6 is within the desired range. The solid residue can have its particle size reduced to be used as a soil conditioner or left coarsely shredded to be used as mulch. Salt properties of the solid residue include nitrogen, potassium, calcium, sulphur, magnesium, and phosphorus [8,9].

Liquid residue: The banana waste has high moisture content and thus high liquid content that remains after digestion. The liquid residue was evaluated for COD as is shown in Table 7 and it ranges from 2000 mg/L to 4000 mg/L. Other nutrients were not measured but from the study of digestion of waste bananas to generate energy in Australia, it was found that the liquid digestate has a high content of Potassium (≈4200 mg/L). These nutrients, therefore, are in excess and have the potential of leaching, thus treatment of the nutrients is recommended.

| % Methane | % Carbon dioxide | |

|---|---|---|

| Blank | 59.24 | 40.76 |

| Leaf | 67.585 | 32.415 |

| Leaf | 65.335 | 34.665 |

| peduncle | 68.79 | 31.21 |

Table 7. Methane and carbon dioxide percentages in the biogas.

Biogas yield: The biogas yield for the blanks in average was as shown in Figure 1, showing that the seeding sludge had no inhibition and was substantially degassed the curve shows that for the first six days, only carbon was degraded but after six days, also organic nitrogen, ammonia, and nitrite are converted. The biogas produced in Figure 1 was subtracted from the average total volume of biogas produced for each substrate to get Figure 2.

The net biogas produced by the three substrates was as shown in Figure 2. According to Verlag des Vereins Deutscher Ingenieure, the stem and the peduncle showed a normal curve for degradation but the leaf had a retarded degradation curve. The stem and the peduncle degraded with ease as compared to the leaf that took time to degrade (Slowly degradable), that even after the 51 days of the experiment it was still being degraded, though the gas production was very little. The stem and the peduncle were substantially reduced in quantity and appearance as compared to the leaf.

Methane yield: Analysis of the biogas produced by gas chromatography enabled the methane part of the gas to be calculated. The methane quantity produced for the various substrates was as shown in Table 8 and the ratio of methane to carbon dioxide is as shown in Table 7. The gas quality was good as there was very little ammonia and hydrogen sulphide that was produced. The methane quantity produced by the various substrates was as shown in Table 8.

| Component | Methane Yield (m3CH4/kg oDM) |

|---|---|

| Stem | 0.125 |

| Peduncle | 0.132 |

| Leaf | 0.062 |

| Waste fruit | 0.367 |

| Peels | 0.322 |

| Mixed | 0.201 |

Table 8. Methane yield from various components of banana waste.

The stem had a maximum methane yield, this can be compared to the results from Muhammad Tahir, et al. which were found to be 0.256 m3CH4/kg oDM at a retention time of 35 days, thus the results obtained were half as much as those from Muhammad Tahir, et al. The difference in methane production could be also attributed to the nature of pre-treatment and storage of the substrate as was explained by Kalia VC, et al. [10]. Banana stem, due to its fibrous nature, is not very favourable for good methanogenesis. Various pretreatment methods are required to breakdown the fibrous nature as was the case in anaerobic digestion of banana stem waste, the relatively higher yields could be due to the pre-treatment and temperature employed. The Peduncle produced 132.33 mLN/g organic dry matter of methane for the 51 days, fibrous residues when used the bacterial population needs time to adjust before being able to degrade the fibre component efficiently. There is no so much literature on the peduncle alone.

Banana leaves from this study where 30% midrib and 70% leaf blade was used produced 62.34 mLN/g organic dry matter of methane. This is low, compared to the peduncle and the stem. Mandal Tanusri, et al. had the value of biogas from banana leaves to be 0.0018 m3 of biogas with a retention time of 90 days and from this study the biogas value was 445 mL of biogas which is comparable results. The leaves are slowly degraded as even after the 51 days there was still some gas, though little being produced this was explained in Coculture fermentation of banana agro-waste to ethanol by cellulolytic thermophilic Clostridium thermocellum CT2, whereby a high concentration of hemicelluloses and lignin, inhibits the availability of cellulose for fermentation by the isolates. Hemicellulose and lignin are complex polymers and are not easily degraded by bacteria hence pre-treatments of banana leaves are aimed at increasing the surface area of cellulose by removing lignin seal, solubilizing hemicellulose and disrupting crystallinity. Pre-treated cellulosic biomass like water treated, alkali-treated, acid-treated, and dried banana leaves are used in fermentation for good results [11,12].

The study has demonstrated that most of the banana wastes can be easily be digested by the anaerobic process, transforming the banana waste biomass into a clean energy vector, biogas. This could offer advantages in terms of expanding industrialization and reducing the number of waste banana products by using the lignocellulosic biomass produced and could be beneficial in the context of global warming.

Journal of Civil and Environmental Engineering received 1798 citations as per Google Scholar report