Case Report - (2021) Volume 11, Issue 9

Received: 28-Aug-2021

Published:

22-Sep-2021

, DOI: 10.37421/2165-784X.2021.11.410

Citation: Justin, Tumsifu M. “Maintenance Strategy and Decision Making Using Analytic Hierarchy Process (AHP) Method.” J Civil Environ Eng 11 (2021): 410.

Copyright: © 2021 Justin TM. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Maintenance has evolved and now plays a vital part in all types of industrial businesses, with an endless number of functions. Numerous sorts of multi-criteria challenges exist in industries or machines, which require a multi-criteria decision-making procedure to be addressed. Each form of maintenance method has its advantages, disadvantages, and benefits. The performance of a machine will be affected by the maintenance tactics utilized to keep it running. These machines needed to be well maintained because a malfunction could result in production losses. Due to issues such as safety, cost, productivity, and customer satisfaction, the maintenance approach utilized on each machine may differ from one to the next. AHP approach is used in this paper to model maintenance strategy and pick possible priorities of maintenance plan utilizing expert decision-making. After safety (38.2%), value added (20%), implementation cost (13.2%), performance measurement (5%), implementation capability (8.2%), support system integration (11.5%) and stock and material management (3.9%) are the next greatest priority considerations on implementation. AALRT system corrective maintenance is the least of our concerns as a result of this. For AALRT's introduction, Total Productive Maintenance (TPM) is advocated. AHP is a multi-criteria decision-making approach for selecting a maintenance plan, which is superior to the traditional experience-based method.

Analytical hierarchy process • Decision making • Maintenance strategy

Maintenance is defined as the operations that are performed to keep machines and equipment in good operating order, such as testing, measuring, replacing, repairing, and adjusting them.

Eisenberger D, et al. [1], Over the last few decades, the density of railway traffic has progressively increased. Some railway links are even operated at or near their capacity limits. Simultaneously, the complexity of railway rolling stock and infrastructural systems, as well as the operational consequences of their breakdowns, has increased dramatically in recent years. As a result of these advancements, a greater demand for efficient operation and maintenance of railway rolling stock systems has emerged. In addition, the rising use of articulated trains has created additional issues for maintenance planning and organization. The adoption of modular maintenance has been one way to deal with these issues. Special focus is being paid to condition-based maintenance methods, which must be reviewed before a transition from traditional maintenance techniques can be adopted. As part of a proper maintenance strategy, it is important to keep in mind the operating characteristics of the system and to satisfy the strategic goals of the firm in terms of dependability and availability. Each component's ideal maintenance strategy has an impact on availability, as well as operational performance and profitability. For this reason, it is necessary to have tools that can assess, compare, and optimize different maintenance procedures, as well as tools that are adaptable and whose results are easy to understand.

Thor J, et al. [2], Since the construction of physical structures such as ships and machinery, maintenance has emerged. Maintaining a machine or restoring it to a state where it can perform a specified function is defined as a collection of all technical and administrative tasks, including supervision and action. Ultimately, the goal of effective maintenance is to discover the appropriate measures that can maintain machine performance at acceptable levels and extend the machine's life cycle. To attain the end goal, different types of maintenance alternatives have been presented. An identical machine in a different production environment may not respond to the same maintenance program due to factors such as humidity, temperature, and job load, for example. There are also a variety of social, environmental, and economic factors that influence the decision-making process. Operator safety risks, government regulations, resource limitations, and budget are some examples of these limits. To achieve high levels of performance in manufacturing businesses, the selection of an appropriate maintenance policy becomes a critical decision-making process.

Maintenance challenges in the railway industry

Maintaining railway cars and their components in a functional state and correcting defects and failures is vital according to the definition of maintenance, which is the activity of keeping machines and equipment in satisfactory functioning condition. Performing maintenance in the wrong way can lead to train delays, hazardous situations, and even fatalities. In addition, these bad events might have a significant impact on the railway's profitability and competitiveness. When evaluating various alternative techniques, it is necessary to model their impact on system performance as well as life cycle costs. Although the complexity of systems has increased, thus have the demands on their performance in terms of reliability, availability, and safety.

Modular maintenance is one of the easiest solutions to deal with the rising complexity and the necessity for the high availability of railway cars. Vehicles constructed with modular maintenance in mind can have their line replaceable units changed as a whole module, and then be altered or repaired independently in the workshop, boosting the vehicle's availability. Despite the increased use of consequently and condition monitoring equipment, as well as the availability of data on the system, the classic maintenance model dominates the majority of maintenance operations in the railway industry: either corrective or periodically scheduled maintenance [1].

A planned maintenance program should include the following important component programs which require using each, based on data from the history file, cost reports, and critical applications:

• Planned maintenance: Here each equipment piece is identified and its maintenance defined.

• Repair maintenance: Equipment fails and the required maintenance is performed.

• Preventive maintenance: Equipment maintenance is scheduled before failure on an estimate of the life of the equipment.

• Predictive maintenance: Maintenance is performed when the need is indicated based on regular or continuous monitoring of the equipment.

• Corrective maintenance: Maintenance is reduced or eliminated by analyzing prior maintenance work and making changes in design, installation materials, or procedures.

• Critical equipment: Equipment failure that adversely affects safety, environment, system availability, yield, quality, or costs.

• Noncritical equipment: Equipment failure that can be identified and repaired within a reasonable period so adverse effects, if any, are within acceptable limits.

Industries are under constant pressure to increase their capabilities for creating value for consumers and improving the cost-effectiveness of their operations as technology advances. There has been a great deal of research done on maintenance strategy options around the world. Some of these will be discussed in this study. When a maintenance alternative must be selected from a pool of maintenance alternatives, decision-making is required. However, regardless of the application, a smart judgment can only be made if the processes are systematically structured, clearly specified, and followed. [3].

Bertolini M, et al. [4], stipulate that a Lexicographic Goal Programming (LGP) approach define the best method strategies for the maintenance of critical centrifugal pumps in an oil refinery for each pump failure mode, this mode allows to take into account the maintenance policy encumbrance in terms of inspection or repair and the manpower involved, linking them to efficiency risk as peats quantified as in FMEC.

The replacement cost, which includes both fixed and variable costs, is directly proportional to the number of units to be replaced. The total cost is a criterion for comparing proposed policies, but none of them will include an accurate mention of the spare parts that the quantity must prepare in the unit time. P. Agency., [5] presented Multi-criteria decision models for two maintenance problems: repair contract selection and spares provisioning. The model incorporates consequences modeled by a multi-attribute utility function in the repair contract problem. Contract cost and system performance, as represented by system interruption time, are the consequences. In the spares provisioning decision model, two criteria (risk and cost) are combined using a multi-attribute utility function.

Bevilacqua M, et al. [5], This research paper discusses the best method of selecting a maintenance strategy in an oil plant refinery that is still in the construction phase. Preventive, condition-based, corrective, and opportunistic maintenance are the five possible alternatives. The best maintenance policy for each of the plant's 200 facilities will be chosen in this oil refinery plant. Following a criticality analysis based on internal oil refinery procedures, the machines are clustered into three homogeneous groups. Several aspects that characterize each of the aforementioned maintenance strategies are arranged in a hierarchical structure and evaluated using only a series of pair-wise judgments using the AHP technique.

Wang L, et al. [6] the aim was to deal with unsettled judgments of decisionmakers, a fuzzy modification of the AHP method is used as an evaluation tool, where unsettled and imprecise judgments of decision-makers are translated into fuzzy numbers for different equipment. An optimal maintenance strategy mix is required to increase production facility availability without significantly increasing investment. Maintenance strategy selection is a classic Multiple Criteria Decision-Making (MCDM) problem. A new fuzzy prioritization method is proposed to avoid the fuzzy priority calculation and fuzzy ranking procedures used in traditional fuzzy AHP methods. By solving an optimization problem with nonlinear constraints, this fuzzy prioritization method can derive crisp priorities from a consistent or inconsistent fuzzy judgment matrix.

Numerous maintenance solutions, including predictive, condition-based, predictive, remote, and preventive maintenance, have evolved as technology has advanced. The main challenges that industries and organizations face with this advanced technology are related to maintenance strategy formulation, selection, and implementation of the most efficient and effective strategies to improve operational capabilities, reduce maintenance costs, and achieve industry competitiveness [7].

Evaluation of maintenance policies and strategy is necessary for conjunction with creating maintenance policies and plans. Reliability of equipment is essential for achieving operational and safety goals, and for reducing total production costs by avoiding catastrophic failures that require significant downtime and workforce this depends on a variety of factors, including machine quality and usage patterns as well as maintenance policies and business strategies. By reducing operating expenses and enhancing capability, the maintenance and asset management department can increase profitability [8].

Field of multiple criteria decision-making method

With the growth of the market and business, it is more crucial than ever to make judgments based on sound logic and reasoning. This will aid in achieving higher outputs and more realistic results while maximizing earnings. Decisionmaking tools are improving daily in a variety of industries, including supply chain management, maintenance strategy selection, the railway industry, the food industry, education, project selection, and so on.

Objectives and goals of maintenance organizations

Maintenance organizations have goals and objectives that dictate the type of maintenance strategy that will be implemented. If these goals and objectives are advanced, and the maintenance organization is recognized as a contributor to the corporate line, a variety of more traditional organizational structures might be adopted. Eti MC, et al. [8], the goals and objectives of maintenance management are:

• Maximum production at the lowest cost, the highest quality, and within optimum safety standards;

• Identify and implement cost reductions;

• Provide accurate equipment maintenance records;

• Collect necessary maintenance cost information;

• Optimize maintenance resources; Optimize capital equipment life;

• Minimize energy usage; Minimize inventory on hand.

Comparative study of maintenance strategies

It is relevant to compare the alternatives by important factors when taking into consideration the maintenance strategies by considering the best approach. These factors may be like reliability level, the percentage in use, advantages, and disadvantages, etc. which simplifies the understanding between various points and conditions.

Operational availability

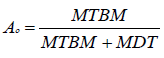

The availability of rolling stock is the likelihood that the rolling stock will perform in a state the transport requirement function under a given design condition at a given instant of time or over a given time interval without failure with the required external resources such as no traffic disturbance, no infrastructure damage or obstacle, and no power disturbance provided. Operational Availability (AO) is the probability that a given item or system will be ready or rolling stock for operation in a system environment. This availability measure considers the total maintenance downtime, i.e. both the active maintenance time and the time waiting for maintenance Aα is the preferred availability measure when assessing a system in a realistic operational environment. The operational availability is expressed as:

Where, MDT is the Mean Down Time = MTTR+MWT

The more available the rolling stock (Vehicle) with selected strategy the higher the availability.

Selection of criteria and sub-criteria

For the optimum maintenance strategy, the selection of criteria is critical. Using tools for Multi-Criteria Decision Making makes it easier to rank these criteria about one another. Machines and equipment used to fulfill company goals will be heavily influenced by factors with high performance, so it's important to study them very thoroughly. Criteria and sub-criteria are most commonly used in the manufacturing industry. Wang L, et al. [6] the important criteria and sub-criteria are classified in the below Tables 1,2.

| S.N. | Factors | Corrective Maintenance | Preventive Maintenance | Condition Based Maintenance |

|---|---|---|---|---|

| 1. | Nature | Run-to-failure | Time-based maintenance | Predictive maintenance, monitor as per assets condition |

| 2. | Basic Philosophy | Allow machinery to run to failure Repair or replace damaged equipment when an obvious problem occurs. |

Schedule maintenance activities at pre-determined time intervals. Repair or replace damaged equipment before an obvious problem occurs. |

Schedule maintenance activities when mechanical or operational conditions warrant. Repair or replace damaged equipment before an obvious problem occurs. |

| 3. | Based on Reliability | Small parts and equipment. Non-critical equipment Equipment is unlikely to fail. Redundant systems |

Equipment subjected to wear. Consumer-able equipment Equipment with known failure pattern. Manufacturer recommendations |

Equipment with random failure patterns. Critical equipment Equipment not subjected to wear. The system's failure may be induced by incorrect preventive maintenance. |

| 4. | Advantages | Low cost Less staff |

Cost-effective in many capital-intensive processes. Flexibility allows for the adjustment of maintenance periodically. Increased component life cycle. Energy savings Reduced equipment or process failure. Estimated 12-18% cost savings over CM. |

Increased component operational life/availability. Decrease in equipment or process downtime. Decrease in costs for parts and labor. Better product quality Improved worker and environmental safety. Energy savings. Improved worker morale. Estimated 8-12% cost savings over PM. |

| 5. | Disadvantages | Increased cost due to unplanned downtime of equipment. Increased labor cost, especially if overtime is needed. The cost is involved with the repair or replacement of equipment. Possible secondary or process damage from equipment failure. |

Catastrophic failure is still likely to occur. Labor intensive Includes performance of unneeded maintenance. Potential for incidental damage to components in conducting unneeded maintenance. |

Increased investment in diagnostic equipment. Increased investment in staff training. The savings potential is not readily seen by management. |

| 6. | Maintenance Strategy used in industry. | 55% Reactive maintenance used in industry. | 31% preventive maintenance used in industry. | 12% predictive maintenance used in industry. |

| 7. | Equation | Breakdown cost = labor + downtime | Preventive Maintenance cost = labor + downtime due to (PM) cost planned shutdown |

Condition Based Maintenance Cost = labor + downtime due to (CBM) cost planned shutdown |

| 8. | Example | Lubricate motors when they become noisy or vibrations occur. | Lubricate pumps every 2000 hours. | Conduct scans on pumps and panels to determine if and when work is required. |

| Criteria | Sub-criteria |

|---|---|

| Cost | Cost of poor maintenance practices |

| Cost of using spare parts | |

| Staff training cost | |

| Safety | Environment effects |

| Personnel safety | |

| Value-Added | Role of professional specialist |

| Spare parts quality and availability | |

| Customer satisfaction | |

| Equipment and Technology | Fault identification |

| feasibility |

Data collection and analysis

When it comes to maintenance planning, data collecting is a critical component of success. To collect data for AHP, a focus group of experts comprised of research, development engineers, and six light rolling stock designers was formed. The professionals must provide all the necessary information before any choice can be made. Focus group members were picked from the locomotive section of the Metal Technology Engineering Corporation (METC). False results may result from improper data gathering, which could lead to the analysis's failure. It was decided to hold two focus groups, the first to complete the revised questioner with consensus and the second to analyze and observe the essential variables indicated by the researchers for the AALRT system. The objective of this analysis was the implementation of the AHP technique. Several questionnaires were produced and given to maintenance experts (Experts), rolling stock, and others to collect information. AHP method or super decision software can be used to calculate pair-wise comparisons after collecting the necessary and important data being studied. MATLAB and other tools may be used to calculate massive data sets via matrix calculations.

It was decided to combine all experts' opinions on maintenance strategy selection and use of decision-making software and analysis to collect data from the discussion group. Using the AHP model data analysis, these results were synthesized throughout the model to produce both the overall strategic alternatives priorities in Table 3 and the priority criteria and sub-criteria in Tables 4, 5.

| Criteria | Sub criteria | Symbol |

|---|---|---|

| Safety | 11 Passenger safety | PS |

| 12 Worker safety | WS | |

| 13 System safety | SS | |

| 21 Hardware cost | HS | |

| Implementation cost | 22 Software cost | SC |

| 23 Operation & maintenance | O&M | |

| 24 training cost | TC | |

| 31 Reliable service | RS | |

| Added value | 32 profits | P |

| 33 vehicle availabilities | VA | |

| 34 Quality service | QS | |

| 41 Budget | B | |

| Implantation capability | 42 Personal capability | PC |

| 43Technology availability | TA | |

| 44 Manger willingness | MW | |

| Maintenance performance | 51 Equipment performance measure | EP |

| 52 Cost performance measure | CP | |

| 53 Process performance measure | PPM | |

| 61 Part availability | PA | |

| Stock and material management | 62 Inventory control | IC |

| 63 Purchase planning | PP | |

| 71 Fleet operation | F | |

| Support system integration | 72 Engineering and technical support | ET |

| 73 Procurement and material management |

PMM | |

| 74 Information technology and communication |

IT |

| Name | Graphic | Ideals | Normals | Raw |

|---|---|---|---|---|

| RCM |  |

0.648696 | 0.227619 | 0.075414 |

| TPM |  |

1.000000 | 0.350888 | 0.116255 |

| CBM |  |

0.618048 | 0.216865 | 0.071851 |

| CM |  |

0.263946 | 0.092615 | 0.030685 |

| PM |  |

0.319225 | 0.112012 | 0.037112 |

| Main criteria (Inconsistency 0.06418) | Result | Sub criteria | Result | Inconsistency |

|---|---|---|---|---|

| PS | 0.4 | |||

| Safety | 0.382 | WS | 0.4 | 0 |

| SS | 0.2 | |||

| RS | 0.276 | |||

| Added value | 0.2 | P | 0.39 | |

| OA | 0.195 | 0.045 | ||

| QS | 0.138 | |||

| HC | 0.346 | |||

| SC | 0.098 | 0.022 | ||

| Implementation cost | 0.132 | O & M | 0.098 | |

| TC | 0.2 | |||

| B | 0.388 | |||

| PC | 0.123 | |||

| Implementation capability | 0.082 | TA | 0.188 | 0.053 |

| MW | 0.299 | |||

| EP | 0.549 | |||

| Maintenance performance | 0.038 | CP | 0.24 | 0.017 |

| PPM | 0.209 | |||

| PA | 0.549 | |||

| Stock and material management | 0.05 | IC | 0.24 | |

| PP | 0.209 | |||

| F | 0.304 | |||

| Support system integration | 0.115 | ET | 0.158 | |

| PPM | 0.39 | 0.044 | ||

| IT | 0.146 |

The use of decision-making tools will simplify a common maintenance plan selection issue, as demonstrated in this study report. With the use of the AHP algorithm approach, the maintenance strategy selection procedure for AALRT is investigated. Preventive maintenance, total productivity maintenance, planned and repair maintenance, reliability-centered maintenance, corrective maintenance, and condition-based maintenance should all be included in any well-planned maintenance program. Multiple criteria decision-making approaches have a wide range of applicability, according to this literature review. Alternative studies, on the other hand, can assist in understanding the problem and in making decisions. A difficult undertaking, selecting a maintenance strategy can be simplified or estimated by looking at several research papers for different firms under varied conditions. AHP algorithm can be used to solve the primary problem of selecting a maintenance strategy. The analysis may also be implemented so that output can be measured by changing the criteria weight, and in addition to the conducted survey, it is recommended that total productive maintenance be implemented at AALRT.

Journal of Civil and Environmental Engineering received 1798 citations as per Google Scholar report