Research Article - (2023) Volume 13, Issue 5

Received: 01-Oct-2023, Manuscript No. IDSE-23-103444;

Editor assigned: 03-Oct-2023, Pre QC No. P-103444 (PQ);

Reviewed: 17-Oct-2023, QC No. Q-103444;

Revised: 23-Oct-2023, Manuscript No. R-103444 (R);

Published:

31-Oct-2023

, DOI: 10.37421/2168-9768.2023.12.389

Citation: Genemo, Gudeta. "Response of Furrow Flow Rate

on Irrigation Water Productivity of Onion and Irrigation

Efficiency Parameters in Western Oromia, Ethiopia." Irrigat Drainage

Sys Eng 12 (2023): 389.

Copyright: �?�© 2023 Genemo G. This is an open-access article distributed under the terms of the creative commons attribution license which permits

unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

This study evaluates the effect of furrow irrigation flow rate on irrigation water productivity, economic water productivity, and irrigation efficiency parameters based on the basis for furrow irrigation design and management in clay loam soil. The treatments were 50%, 70%, 85%, 100% and 120% Qmax, respectively. A randomized complete block design was used with three replications for the treatments. Based on the results, furrow irrigation inflow rate had a highly significant (P<0.01) effect on onion yield components and marketable yield. Based on the study, application of T3 (85% Qmax) resulted in the highest number of plant height, bulb diameter, bulb length and bulb weight. It was found that T3 yielded the highest marketable yield (19.61 tons/ha), while T1 yielded the lowest (13.59 tons/ha). A maximum of 3.72 kg.m-3 irrigation water productivity was achieved at T1, and a minimum of 1.89 kg.m-3 was obtained at T5. Under treatment T3 (85% Qmax), the highest economic water productivity of 35.76 ETB.m-3 was attained. In total, 4164.8 m3 of water was saved from varying furrow irrigation inflow rates per hectare, which was used to irrigate an additional 1.61 ha, giving a total yield of 24.39 tons per hectare. At T3, the best water application efficiency, requirement distribution efficiency, and total distribution efficiency were 63.75%, 89.92% and 92.62%, respectively. Application efficiency increased from 55.8% to 65.32% when furrow irrigation inflow rate increased from T1 to T3 and deep percolation loss dropped inversely from 44.52% to 36.25%. According to the results, application of T3 (85% Qmax) improved irrigation efficiency, onion marketable yield, economic water productivity and irrigation water productivity. The outcomes of this study could be useful in the management, planning and operation of furrow irrigation systems in clay loam soil.

Flow rate • Water productivity • Irrigation efficiency • Onion • Economic water productivity

Agriculture, as the main economic activity in our country and the largest consumer of water, although the overall efficiency of surface irrigation at farmer's fields was low. Furrow irrigation is the most popular surface irrigation technology used to apply water to planted fields. However, farmers in Ethiopia use furrow irrigation, which results in significant deep percolation losses and unequal water delivery. These not only result in substantial losses of scarce water, but also in waterlogging and salinity issues. Irrigation water management necessitates improvements in the efficiency of present water application and on-farm water management strategies for sustainability over the long term. In this arrangement, farmers commonly move water higher via the hose as they approach the furrow end to lessen the flow rate [1]. It is quite simple to irrigate the following furrow instead of lowering the flow rate. Thus, the following furrow will begin watering with a low flow rate that can be increased later when the preceding furrow stops irrigation.

Several variables are examined during furrow irrigation design to determine the value of the variable parameters in order to achieve optimal application efficiency. These parameters are the furrow irrigation inflow rate and furrow length. The inflow rate is one of the most important elements in affecting the outcomes of an irrigation event, although the optimal furrow length is often determined by the level at which the system parameters and system variables are fixed. Similarly, stated that increasing furrow irrigation inflow rate from 1.16 lit/ sec to 3.34 lit/sec increases water application efficiency from 74.9% to 80.9% for furrow length 50 m in clay soil. Despite its relatively low application efficiency, insufficient effort is being done to improve its management and efficiency in furrow irrigation.

Furrow irrigation system efficiency is determined by the interaction of various elements including as design variables, irrigation system management, and field conditions. However, altering the furrow irrigation inflow rate can improve irrigation uniformity and reduce surface runoff, resulting in increased application efficiency [2]. As a result, the goal of this work was to assess the influence of altering furrow irrigation flow rate on irrigation water productivity, economic water productivity and irrigation efficiency parameters.

This research area was located at Bako Woreda Dambi Dima kebele, West Shewa zone, Oromia regional state, at an altitude of 1590 m above sea level and in 9°06' N and 37°09' E latitude and longitude, respectively [3]. The mean monthly minimum and maximum temperatures in the area were 13.7°C and 28.4°C, respectively, while the mean monthly annual dependable and effective dependable rainfall in the area were 808.5 mm and 482 mm, respectively (Table 1).

| Monthly rainfall data | ||

|---|---|---|

| Climatic station: Bako RC | Effective rain fall method: Dependable rain fall (FAO/AGLW formula) | |

| Month | Dependable rain fall (mm/month) | Effective dependable rain fall (mm/month) |

| January | 0 | 0 |

| February | 0 | 0 |

| March | 14.07 | 0 |

| April | 32.62 | 9.6 |

| May | 95.72 | 52.6 |

| June | 161.3 | 105 |

| July | 212.78 | 146.2 |

| August | 179.2 | 119.4 |

| September | 90.46 | 48.4 |

| October | 18.18 | 0.9 |

| November | 4.12 | 0 |

| December | 0 | 0 |

| Year | 808.5 | 482 |

| Effective dependable rain formula | Peff=0.6× p-10 for P month less than 70 mm | |

| Peff=0.8 × p-24 for P month greater than 70 mm | ||

Table 1. Dependable and effective dependable rain fall near experimental site station.

Experimental design and treatment

An experiment was designed with five levels of furrow irrigation inflow rate under a conventional furrow irrigation system. The treatments were 50%, 70%, 85%, 100% and 120% Qmax. 100% Qmax (maximum non-erosive furrow inflow rate) was assigned as the control [4]. The predefined furrow irrigation inflow rate was determined based on soil textural class and furrow bed slope.

The experimental treatments were T1=50% Qmax, T2=70% Qmax, T3= 85% Qmax, T4=100% Qmax, and T5=120% Qmax. According to the equation, the maximum non-erosive inflow rate for the furrow irrigation system was determined (Table 1).

Where; Qmax=Maximum flow rate, l/s

S=Furrow bed slope, %

α and β are coefficient of parameters based on soil group

| Soil group | α (l/s) | β |

|---|---|---|

| Heavy textured soil | 0.892 | 0.937 |

| Medium heavy textured | 0.988 | 0.55 |

| Medium texture | 0.613 | 0.733 |

| Light texture | 1.111 | 0.615 |

| Very light texture | 0.665 | 0.548 |

Table 2. Coefficient parameters for furrow maximum flow rate.

The experimental plot had an average of furrow bed slope of 0.6% and clay loam in textural class (medium heavy textured soil group). Based on these the value of α and β were determined (Table 2). Accordingly, the maximum nonerosive furrow inflow rate (Qmax) at 50, 70, 100, and 120% Qmax were 2.52 m3/hr, 3.31 m3/hr, 4.03 m3/ hr, 4.72 m3/hr and 5.65 m3/hr. Finally, the experimental field was arranged in a Randomized Complete Block Design (RCBD) with three replications for five levels of treatment [5]. Each replication had five treatments, or plots, and each plot had four furrows with a 2.4-meter width and a 25-meter length. The treatments were arranged in three blocks. The block and plot spacings were 1.5 m and 0.5 m respectively. In accordance with, the equation was used to calculate the amount of time needed to deliver the desired water depth into each furrow [6].

Where; t is the application time (hr), Da is the depth of water applied (cm), L is the furrow length (m), q is the flow rate (l/s), W is the furrow spacing (m).

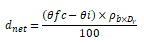

The net depth of irrigation is the quantity of water necessary to raise the effective root zone soil moisture level to field capacity. It was therefore the difference in field capacity and soil moisture content in the root zone prior to irrigation. The following relationship exists;

Where; dnet=Net amount of water to applied during irrigation (cm)

θfc=The moisture content at field capacity in the rootzone by volume (%)

θi=Initial moisture content before irrigation in the root zone (%)

Dr=Depth of root zone (cm)

Pb=Bulk density of the soil in the root zone (g/cm3)

The gross depth of irrigation water is calculated by dividing the net irrigation depth by the application efficiency [7]. The following calculation was used to calculate the total amount of irrigation water required.

Irrigation water productivity and economic water productivity

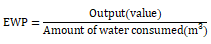

Irrigation water productivity was measured by dividing the yield to seasonal evapotranspiration by the total irrigation water applied, and it was computed as follows:

Where; IWP is the irrigation water productivity (kg/m3), Ya is the actual yield (kg) and TWAP is the total (gross water applied to the field (m3).

Economic water productivity measures the economic benefit per unit of water consumed. It was calculated by:

Where; EWP is the economic water productivity in ETB.m-3, output is the product of marketable yield and market price of onion crop in ETB.

Irrigation efficiency parameters

To determine irrigation efficiency parameters, soil samples from each plot were obtained using a manually operated soil auger and standard method (gravimetric moisture determination method) as described.

Application efficiency

Water application efficiency (Ea) was defined as the ratio between the volume of water retained in the root zone of the soil profile following irrigation and the total volume of water applied during the irrigation process [8].

Where; Ea is the Application Efficiency (%), ZS is the depth of water retained in the root zone (mm) and Z is the depth of water applied to the furrow (mm).

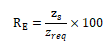

Requirement efficiency

The Requirement Efficiency (RE), also known as water storage efficiency, assesses the performance of the amount of water stored in the root zone following irrigation.

Where; RE is the Requirement Efficiency (%), ZS is the depth of water retained in the root zone (mm) and Zreq is the depth of water required in rootzone prior to irrigation (mm).

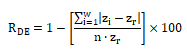

Requirement distribution efficiency

The Requirement Distribution Efficiency (RDE) evaluates the effects of applied water distribution in respect to crop water requirements and implies that an excess of applied water has no significant impact on crop production [9]. It can be stated numerically as:

Where; zi is the depth of water infiltrated at point I (m), zr is the depth of water required by the crop in each irrigation and obtained from irrigation schedule (m3 m-1), W is the number of observations in which zi is less than or equal to zr and n is the total number of observations.

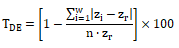

Total distribution efficiency

TDE explains the distribution of applied water in proportion to crop water requirements, taking into consideration shortages and excesses [10]. It is defined as follows:

Where; zi is the depth of water infiltrated at point I (m), zr is the depth of water required by the crop in each irrigation and obtained from irrigation schedule (m3 m-1), W is the number of observations in which zi is less than or equal to zr, and n is the total number of observations.

Deep percolation loss

A deep percolation loss can be calculated indirectly from the measured values of application efficiency and runoff ratio.

DPL=100-Ea-RR

Since the study was conducted under farmers’ field conditions, the furrows were closed-end (end dyked), runoff ratio was neglected. Therefore, deep percolation loss was calculated as:

DPL=100-Ea

Effect of furrow irrigation inflow rate on yield and yield component parameters of onion.

Plant height

Analysis of the data indicated a highly significant (P<0.01) difference in all furrow irrigation inflow rate (Table 3). The minimum (45.7 cm) and maximum (55.46 cm) plant heights were observed at the minimum furrow irrigation flow rate (T1) and maximum furrow irrigation flow rate (T4), respectively. Higher plant height correlated with higher irrigation water application, while lower plant height was associated with low irrigation water application (Table 3) [11]. This finding is consistent with that of, who discovered that the plant height of Onion grew with higher irrigation water application levels and decreased with decreased irrigation water application levels.

| Treatment | Plant height (cm) | Bulb diameter (cm) | Bulb length (cm) | Bulb weight (gram) | Marketable yield (ton/ha) | Irrigation water productivity (Kg .m-3) | Economic water productivity (ETB.m-3) |

|---|---|---|---|---|---|---|---|

| T1 | 45.75 | 2.8 | 5.7 | 68.82 | 13.59 | 3.72 | 30.45 |

| T2 | 48.43 | 3.2 | 6.4 | 70.45 | 16.97 | 3.32 | 32.93 |

| T3 | 54.76 | 3.7 | 6.7 | 74.75 | 19.61 | 3.16 | 35.76 |

| T4 | 55.46 | 3.3 | 7.8 | 76.54 | 17.86 | 2.44 | 31.59 |

| T5 | 51.87 | 3.2 | 6.87 | 75.89 | 16.59 | 1.89 | 29.89 |

| Significance | *** | *** | ** | *** | *** | ** | ** |

| LSD (0.05) | 4.83 | 2.4 | 1.7 | 3.2 | 4.5 | 2.6 | 4.2 |

| CV (%) | 9.45 | 3.45 | 4.3 | 6.8 | 8 | 5.34 | 7.6 |

Note: ***=highly significant at 0.01, **=significant at 0. 05

Table 3. Summary analysis the effect of varying furrow in flow rate on yield, yield Components, irrigation water productivity and economic water productivity of onion.

Bulb diameter

The effect of furrow irrigation inflow rate on bulb diameter was extremely significant (P<0.01) (Table 3). The highest bulbdiameter, 3.7 cm, was obtained at maximum furrow irrigation inflow rate (T3), and the smallest, 2.8 cm, was produced at minimum furrow irrigation flow rate (T1).

This conclusion was consistent with, who observed that higher irrigation levels increased the quantity of nutrients partitioned to the bulbs and enhanced bulb diameter.

Bulb length

ANOVA revealed that the influence of furrow irrigation inflow rate on bulb length was extremely significant (P<0.01) (Table 2). The longest bulb length was 7.8 cm at T4 and the shortest bulb length was 5.7 cm at T1 (Table 3). This demonstrates that greater irrigation water application resulted in maximum onion bulb length [12]. Also observed a significant increase in bulb yield and yield components due to appropriate hydration in the root zone, which was used to boost plant growth, yield, and yield components (such as bulb length and bulb diameter).

Average bulb weight

The mean bulb weight was a highly significant (P<0.01) effect of furrow irrigation flow rate (Table 3). T4 had the highest average bulb weight of 76.54 gm and T1 had the lowest average bulb weight of 68.82 gram. This is due to an increase in bulb weight caused by an increase in application water depth. This conclusion was consistent with the findings.

Marketable bulb yield

ANOVA revealed that the effect of furrow irrigation inflow rate on marketable bulb yield was highly significant (P<0.01). For T1, T2, T3, T4, and T5 inflow rates, the mean values of marketable onion bulb yield were 13.59, 16.97, 19.61, 17.86 and 16.59 ton/ha, respectively (Table 3). The marketable bulb yield of onion increases as the furrow irrigation inflow rate increased until it reached the design limit (Qmax), at which point yield began to fall [13]. This occurs as a result of excessive water application, which leaches off vital plant nutrients, stressing the plant's nutrition.

Marketable Yield of onion (MY) and furrow irrigation Flowrate (FR) relationship was developed by using regression analysis. The result showed that second ordered polynomial was best fitting model to explain the response of marketable yield onion to altering furrow irrigation flow rate. Figure 1, showed that significantly a polynomial relationship between MY and FR as expressed below.

MY=0.2978FR3+5.199FR2+27.81FR-28.365, R2=93%,

The result showed that about 93% of variation in onion yield could attribute to the variation of in furrow irrigation flow rate.

The minimum marketable onion bulb yield was 13.59 ton/ha at the small furrow inflow rate (T1), and the maximum marketable onion bulb yield was 19.61 ton/ha at the maximum inflow rate (T3) (Table 3).

Higher inflow rates improved irrigation consistency, which boosted marketable onion production indicated that maximum orifice flow rate resulted in increased Wheat grain yield as well as higher distribution efficiency.

Effect of furrow inflow rate on economic and irrigation water productivity

Furrow irrigation inflow rate had a significant (P<0.05) impact on irrigation water productivity. The mean irrigation water productivity values for T1, T2, T3, T4, and T5 irrigation flow rates were 3.72, 3.32,3.16, 2.44 and 1.89 kg/m3 (Table 3). The highest irrigation water productivity was 3.72 kg/m3, 3.32 kg/m3 at T1 and T2, and the minimum irrigation water productivity was 2.44 kg/m3, 1.89 kg/m3 at T4 and T5 inflow rates, respectively (Table 3). Irrigation water productivity and irrigation water use efficiency increase as irrigation volume or application depth is reduced.

Furrow irrigation inflow rate influenced economic water productivity significantly (P<0.05). For T1, T2, T3, T4, and T5 irrigation flow rates, the mean values of economic water productivity were 30.45, 32.93, 35.76, 31.59, and 29.89 (ETB/m3) (Table 3).

The results show that T3 (85% Qmax) produced the highest mean maximum economic water productivity of 35.76 ETB m-3 compared to the other treatments [14]. This is stated to mean that using 1m3 of irrigation water under T3 yields 35.76 ETB, while using 1 m3 of irrigation water under the other four treatments yields 30.45, 32.93, 31.59, and 29.89 ETB, respectively.

The total amount of water saved as a result of altering furrow irrigation inflow rate was calculated and compared to the maximum non-erosive flow rate to the experimental plot [15]. As a result, total amount of water saved as a result of altering furrow irrigation inflow rate was 4164.8 m3 per hectare, which was used to irrigate an additional 1.61 ha, yielding a total yield of 24.39 ton/ha (Table 4).

| Treatment | Marketable onion yield (ton/ha) | Dnet (m3/ha) |

Dg (m3/ha) | Water saved from dnet (m3/ha) | Water saved (%) | IWp (Kg/m3) |

Additional area Irrigated from water saved (ha) |

Gained yield from additional irrigated area (ton/ha) |

|---|---|---|---|---|---|---|---|---|

| T1 | 13.59 | 2192 | 3653.3 | 2192 | 49.99 | 3.72 | 1 | 13.59 |

| T2 | 16.97 | 3068.73 | 5114.6 | 1315.2 | 30 | 3.32 | 0.43 | 7.27 |

| T3 | 19.61 | 3726.3 | 6210.5 | 657.6 | 15 | 3.16 | 0.18 | 3.53 |

| T4 | 17.86 | 4383.9 | 7308.5 | 0 | 0 | 2.44 | 0 | 0 |

| T5 | 16.59 | 5260.7 | 8767.8 | 0 | 0 | 1.89 | 0 | 0 |

| 4164.8 | 1.61 | 24.39 |

Table 4. Amount of water saved and additional area irrigated relative to maximum non erosive furrow inflow rate.

Effect of furrow irrigation inflow rate on Irrigation Efficiency parameters

Application efficiency: The effect of furrow irrigation inflow rate on application efficiency (Ea) was highly significant (P<0.01) (Table 5). The mean application efficiency values were 55.48%, 61.54%, 63.75%, 65.32% and 60.89% for T1, T2, T3, T4, and T5 inflow rates, respectively. Application efficiency increases as flow increases until it reaches the design limit (Qmax), at which point it starts declining. This result is supported by, who indicate that application efficiency increases as furrow flow rate increases.

Requirement efficiency: The influence of furrow irrigation inflow rate on requirements efficiency was highly significant (P<0.01) (Table 5). The mean requirements efficiency values for T1, T2, T3, T4 and T5 inflow rates were 80.22%, 77.02%, 75.83%, 74.07% and 70.89%, respectively. The minimum requirement efficiency was reached at the largest furrow irrigation inflow rate (T5), which was 70.89%, while the maximum requirement efficiency was obtained at the small furrow irrigation inflow rate (T1), which was 80.22%.

Requirement distribution efficiency: ANOVA Table 5 shows that the influence of furrow irrigation inflow rate on Requirement Distribution Efficiency (RDE) was extremely significant (P<0.01). The mean total distribution efficiency values for T1, T2, T3, T4, and T5 furrow inflow rates were 84.02, 85.57, 87.92, 92.11, and 95.42%, respectively (Table 5). The minimum requirement distribution efficiency was 84.02%at the small inflow rate (T1), and the highest requirement distribution efficiency was 95.42% at the larger inflow rate (T5) (Table 5).

This is because increasing the rate of furrow inflow minimizes the differential in wetting throughout the furrow length, which contributes to increased requirement distribution efficiency. Revealed that the higher the flow rate, the larger the distribution efficiency, and increasing the flow rate increased the distribution efficiency.

Total distribution efficiency: As indicated in Table 5, the influence of furrow irrigation inflow rate on total distribution efficiency (Christiansen's uniformity Coefficient) was very significant at (P<0.01). The mean overall distribution efficiency values for T1, T2, T3, T4, and T5 furrow inflow rates were 89.05%, 90.80%, 92.62%, 93.58% and 95.39%, respectively. Total distribution efficiency increases with furrow inflow rate (Table 5). T1 had the lowest overall distribution efficiency of 89.05%, while T5 had the highest total distribution efficiency of 93.58% (Table 5). Discovered a direct relationship between furrow irrigation flow rate and total distribution efficiency.

Deep percolation loss: According to ANOVA, the effect of furrow irrigation inflow rate on deep percolation loss was highly significant (P<0.01). The mean values of deep percolation loss for T1, T2, T3, T4 and T5 furrow irrigation inflow rates were 44.52%, 38.46%, 36.25%, 34.68% and 39.11%, respectively (Table 4). As the furrow irrigation inflow rate increased, deep percolation loss decreased (Table 5). Similarly, [Deep percolation loss: According to ANOVA, the effect of furrow irrigation inflow rate on deep percolation loss was highly significant (P<0.01). The mean values of deep percolation loss for T1, T2, T3, T4 and T5 furrow irrigation inflow rates were 44.52%, 38.46%, 36.25%, 34.68% and 39.11%, respectively (Table 4). As the furrow irrigation inflow rate increased, deep percolation loss decreased (Table 5). Similarly, [9] found that when furrow inflow rate increases, deep percolation loss decreases. The minimum deep percolation loss was 34.68% at the maximum furrow irrigation inflow rate (T4), and the maximum deep percolation loss was 44.52% at the small furrow irrigation inflow rate (T1) (Table 5).] found that when furrow inflow rate increases, deep percolation loss decreases. The minimum deep percolation loss was 34.68% at the maximum furrow irrigation inflow rate (T4), and the maximum deep percolation loss was 44.52% at the small furrow irrigation inflow rate (T1) (Table 5).

| Treatment | Application efficiency (%) | Requirement efficiency (%) | Requirement distribution efficiency (%) | Total distribution efficiency (%) | Deep percolation loss (%) |

|---|---|---|---|---|---|

| T1 | 55.48 | 80.22 | 84.02 | 89.05 | 44.52 |

| T2 | 61.54 | 77.02 | 85.57 | 90.80 | 38.46 |

| T3 | 63.752 | 75.83 | 87.92 | 92.62 | 36.25 |

| T4 | 65.32 | 74.07 | 92.11 | 93.58 | 34.68 |

| T5 | 60.89 | 70.89 | 95.42 | 95.39 | 39.11 |

| Significance | *** | *** | *** | *** | *** |

| LSD (0.05) | 1.58 | 2.34 | 1.89 | 1.75 | 1.58 |

| CV (%) | 4.65 | 7.45 | 3.5 | 2.89 | 4.65 |

Table 5. Summary analysis of the effect furrow inflow rate on Irrigation Efficiency parameters.

According to the findings of the current study, furrow irrigation flow rate is the primary management and design variable that farmers and irrigation designers can control in order to increase crop yield, irrigation water productivity, economic water productivity and irrigation efficiency parameters. The analysis revealed that the effect of furrow irrigation inflow rate on yield component, marketable yield of onion, irrigation and economic water productivity was significant (P<0.05). When compared to other treatments, the study found that using T3 (85% Qmax) results in a higher number of plant heights, bulb diameters, bulb lengths, and bulb weights. The minimum marketable onion bulb yield was 13.59 ton/ ha at T1, and the maximum marketable onion bulb yield was 19.61 ton/ha at T3. The maximum (3.72 kg.m-3) and lowest (1.89 kg.m-3) irrigation water productivity was obtained at T1 and T5, respectively. The total amount of water saved as a result of altering furrow irrigation inflow rate was 4164.8 m3 per hectare, which was used to irrigate an additional 1.61 ha, yielding a total yield of 24.39 ton/ha. At T3, the maximum water application efficiency, requirement distribution efficiency, and total distribution efficiency were 63.75%, 89.92% and 92.62%, respectively. As the furrow irrigation inflow rate increased from T1 to T3, application efficiency increased from 55.8% to 65.32%, while deep percolation loss dropped from 44.52% to 36.25%. The results showed that using T3 (85% Qmax) improved economic water productivity, irrigation water productivity, marketable onion output and irrigation efficiency parameters. Finally, the findings of this study may be useful in the planning, design, management, and operation of furrow irrigation systems in clay loam soil.

Irrigation & Drainage Systems Engineering received 835 citations as per Google Scholar report