Research Article - (2023) Volume 12, Issue 4

Received: 03-Aug-2022, Manuscript No. IDSE-22-71191;

Editor assigned: 08-Aug-2022, Pre QC No. IDSE-22-71191(PQ);

Reviewed: 23-Aug-2022, QC No. IDSE-22-71191;

Revised: 03-Oct-2022, Manuscript No. IDSE-22-71191(R);

Published:

11-Oct-2022

, DOI: 10.37421/2168-9768.2022.11.385

Citation: Abshiro, Fikadu Kinfe, Kidane Tesfa Michael Gadisa

and Mayet Feleke Adugna. "Evaluation of Sprinkler Heads at Beles

Sugar Development Project." Irrigat Drainage Sys Eng 11 (2022): 363.

Copyright: © 2022 Abshiro FK. This is an open-access article distributed under the terms of the creative commons attribution license which permits unrestricted

use, distribution and reproduction in any medium, provided the original author and source are credited.

Beles sugar development project has faced the problems of inadequate and poor uniformity of irrigation water. Thus, the system has failed to meet the crop water demand. Having this, the plantation section irrigators were made the two combined sprinkler heads in one HDPE pipe which is fitted with the main riser like the single sprinkler head. By applying the modified combine sprinkler heads, the cane under water stress has recovered soon relative to the existing sprinkler head. The correlated challenge was the irrigation set hour of the modified combine sprinkler heads was not known and its technical comparative discharge advantage was not determined. Thus, this research work was undertaken to compare the modified two combined sprinkler heads with the normal single sprinkler head and to develop sprinkler set hour under the current operational situation. The parameters evaluated were sprinkler discharge, net depth of water application, gross depth of water application and sprinkler set time. The modified combined sprinkler heads had 43% more discharge than the normal single sprinkler head at the same hydrant pressure of 2.5 bar. The sprinkler set time of the modified combine sprinklers heads at the growth stage of 0-3, 3-6, 6-15 and above 15 months was reduced by 43.5%, 41.2%, 43.5 % and 42.6% respectively compared to the normal single sprinkler head.

within the same design irrigation interval of 15 days and 18 × 18 m sprinkler spacing, the modified combine sprinkler heads at 0-3, 3-6, 6-15 and above 15 growth stage has the sprinkler positions and area coverage of 28, 18, 14 and 9 and 0.907, 0.583, 0.454 and 0.292 ha respectively. The modified combine sprinkler heads is better to cover the area with short time and better amount with relative to the normal single sprinkler head.

Sprinkler head • Discharge • Sprinkler set time • Sprinkler position • Sprinkler spacing • Depth of application

Beles sugar development project irrigation system is gravity overhead hose move sprinkler irrigation. Sprinkler irrigation system has more several advantages than furrow irrigation system, although it has its own limitation, wind may distort the sprinkler pattern (it affects the uniformity application of irrigation water), clogging of sprinklers due to unclean water and entrance of debris, heavy soils with poor intake capacity cannot be irrigated efficiently [1].

Irrigation proficiency is vital constituent of any irrigation system managing because of its association by the water losses and energy and the labor wants for executing a viable irrigation system. Solomon wrote that irrigation uniformity is the non-uniformity in the quantities of water applied to positions within the watered area. Uniformity is associated to crop yield by the effects of below or over watering.

Insufficient water in the soil creates high soil moisture tension, lack of plant water and reduced crop yields, whilst surplus water may also decrease yield by mechanisms such as washing of plant nutrients, improve disease occurrence or delayed growth of commercially valued parts of crops [2].

Significant Factors which affect the sprinkler distribution uniformity are number of Nozzles, size, shape, operating pressure, sprinkler spacing, humidity, more importantly wind condition, and management factors such as irrigation frequency, irrigation per day, equipoising of laterals and watering blocks of several adjacent laterals at once [3].

Four factors which are critical to achieve high levels of performance for any irrigation systems are: Irrigation timing, depth of application, uniformity, and water supply characteristics. Therefore, irrigation system design must take into account the water supply characteristics to ensure that farmers have sufficient flexibility to irrigate at the right time and apply the right amount of water [4].

In view of the above background, similarly beles sugar development project has faced the problems of inadequate and poor uniformity of irrigation water. The sprinkler irrigation system is designed to work at a hydrant operating pressure of 4 bars. As according to the normal working condition, field observation measurement and study undertaken by Abshiro FK, Singh P, most of fields were working below the design capacity of 4 bar hydrant operating pressure except rare fields which were located in the lowest elevation. As the field observation taken, it is not adequate even it is irrigated more than 24 design set hour. It also easily affected by wind drift due to the low operating pressure, and water application uniformity is becoming poor. Thus, the system has failed to meet the crop water demand; the cane growth performance is becoming poor. Having this, the plantation section irrigators were initiated and made the two combined sprinkler heads in one HDPE pipe which is fitted with the main riser like the single sprinkler head.

By applying the modified combine sprinkler heads, the cane under water stress has recovered soon relative to the existing sprinkler head. Having this modification, the correlated challenge was the irrigation set hour of the modified combine sprinkler heads was not known. Comparing the modified combine sprinkler heads with the normal single head sprinkler and developing its irrigation set hour is very important. Therefore, this study was conducted to compare the modified two combined sprinkler heads with the normal single sprinkler head and to develop sprinkler set hour under the existing working condition.

Description of the study area

Tana beles integrated sugar development project is located in the Western periphery of Amhara National Regional State, 149 km and 70 km from bahir dar and dangela towns, respectively. A totally of 72,944 ha of land were demarcated for tana beles integrated sugar development project, among this 37,207 ha and 35,737 ha were located at upper beles and ayma respectively.

The project undergoing both sprinkler and surface irrigation system, the sprinkler irrigation covers 80% of total command area.

The study area has low to medium relief differences with an altitude range of 806 meters to 1242 meters above sea level. The project area is characterized as warm humid climate with mean annual humidity reaching to 80% and the maximum temperature fluctuating between 37°C in April and 27°C in July, while the minimum temperature variation is bounded between 12°C (December) and 19°C (July). Over all, the project area is considered to be humid with relative humidity ranging between 66 and 92%. The mean annual rainfall around the irrigation scheme is 1576 mm (from 1986-2006) feasibility and design study of TBISDP (2013). Verti sols cover more than 50% of the command area among the five categories of soil types [5].

Description of the modified combine two sprinkler heads fitting

The materials used to modify the two sprinkler heads were; HDPE pipe, riser power cup, hose adapter, sprinkler heads, saddle and end caps. The HDE pipe was burst in to three openings which were considered the sprinkler heads and main riser fittings. The two sprinklers head was fitted at each of the two ends of the HDPE pipe openings by the aid of riser power valve, adapter and saddle. Finally, the two fitted sprinklers head was fitted with the main riser head through the middle opening using the saddle, adapter and riser power valve. The two ends of the HDPE pipe openings were close using end caps. All the materials used to modified this work were available locally in field, some of each were non usable. The picture of the modified sprinkler heads was shown in Figure 1.

Materials used

The materials used to evaluate the modified sprinklers head were; flexible plastic water hose 3.5 m length, water holding container, stop watch, Pressure gauge for measuring hydrant pressure, and measuring graduated for nozzle discharge measurement, and others.

Data collection

Pressure measurement: The actual hydraulic valve operating pressure which delivers water for the sprinklers were measured using hydrant pressure gauge. The gauge was held from the hydrant valve to record the operating pressure of the hydrant. The hydraulic operating pressure measurement was taken before the sprinkler discharge was record.

Sprinkler discharge measurement: The volumetric discharge of the normal sprinkler and the modified two sprinkler heads was measured with the aid of 3.5 m flexible plastic water hose connecting with nozzle and collected using plastic water bucket container. The test was done at TM2_N24 field. The time taken to fill the bucket was recorded and the discharge is determined using the equation:

q=v/t

Where,

q is the discharge of sprinkler (l/s),

v is the volume of water collected in liters (l),

t is the time taken to fill container (s).

Root depth and Soil moisture parameters: Root depth at different cane growth stages was referred (Table 1).

| Cane age (months) | Root depth (cm) |

|---|---|

| 0-3 | 30 |

| 03-Jun | 45 |

| Jun-15 | 60 |

| Above 15 | 90 |

Soil moisture content (FC and PWP) and bulk density for clay soil were adopted from which were conducted at Beles research center and tested at Amhara design and supervision works enterprise, Bahirdar, Ethiopia [6].

Parameters analysis

Sprinkler discharge: Sprinkler discharge for normal and the two modified sprinkler heads was estimated using equation 1.

Net depth of water application (dn).

Net depth of irrigation water required was estimated using equation 2:

Where, TAW is Total available water for the soil sample (%).

TAW=(FC-PWP)*, FC is moisture content of the soil at filed capacity (%), and PWP is moisture content of the soil at permanent wilting point (%), ρi is the soil bulk density(1 gm/cm3 ), Dr is maximum effective root depth (m) differ for different growth stage, and p is moisture depletion factor, previous studies of Habib and Solomon the optimum factor of depletions used in their studies for sugarcane was in between 0.50 to 0.65 which was also proposed by Booker Tate for Metahara sugar estate soils, and was in agreement with recommended 0.55 by Rao and 0.65 by FAO. Considering 90% concentration of effective rooting depth at top 60 cm was appropriate to estimate soil moisture deficit for irrigation timing of sugarcane Booker Tate. This was to protect the crop from moistures stress in its effective root area. Thus, 60% soil moisture depletion factor was used for this study.

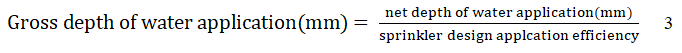

Gross depth of water application (dg): The gross depth of irrigation water applied of the study area was estimated using equation 3 according to [7].

The net depth of water application was according to equation 2, whereas the sprinkler design application efficiency was according to the design document which is 70%.

Sprinkler set time (T): The normal sprinkler and the two modified sprinkler heads set time were determined using equation 4.

Where, dg is the gross depth of water application (cm), Ig is gross sprinkler water application rate (cm/hr) Ig was estimated using the equation 5.

Where, q is the actual sprinkler discharge (lit/sec), Sm is lateral spacing (m), and Sl is sprinkler spacing (m). For this study the spacing of 18 × 18 m was used according to the design.

Sprinkler discharge

The sprinkler nozzle discharge obtained was measured at a hydrant operating pressure of 2.5 bars. The normal sprinkler head discharge obtained was 0.56 m3/hr. The two modified sprinkler head obtained discharge was 0.98 m3/hr and 0.49 m3/hr for each sprinkler head. The summary of the sprinkler discharge, nozzle diameter and operating pressure were shown in Table 2.

| S/N | The normal sprinkler head | The modified sprinkler heads |

|---|---|---|

| Sprinkler discharge (m3/hr) | 0.56 | 0.98 |

| Nozzle diameter (mm) | 5.1 | 5.1 |

| Hydrant pressure (bar) | 2.5 | 2.5 |

As shown in the Table 2 the modified sprinkler heads had 43% more discharge than the normal sprinkler head at the same hydrant pressure of 2.5 bar. Due to the discharge variation shown in the table and as field observation done, the modified sprinkler heads had relatively a tendency to wet the soil surface and resist wind drift effect. In addition, the table showed that the system is working under the design capacity of 4 bar hydrant operating pressure.

Net depth (dn) and gross depth (dg) of application

The net and gross depths of application estimated for the test area of verti (clay soil) for different growth stage were shown in Table 3 below.

| Cane growth stage (month) | Net depth of application (dn) in (mm) | Gross depth of application (dg) in (mm) |

|---|---|---|

| 0-3 | 27.59 | 39.42 |

| 03-Jun | 41.39 | 59.12 |

| Jun-15 | 55.18 | 78.83 |

| Above 15 | 82.77 | 118.25 |

Sprinkler set hour

Sprinkler set time for the normal and modified sprinkler heads for the test area of verti (clay soil) was shown in Table 4 below.

|

The normal sprinkler |

The modified sprinkler heads |

|---|---|---|

Can growth age (month) |

Sprinkler set time (hr) |

Sprinkler set time (hr) |

0-3 |

23 |

13 |

03-Jun |

34 |

20 |

Jun-15 |

46 |

26 |

Above 15 |

68 |

39 |

As stated in the Table 4, the sprinkler set time of the modified combine sprinklers heads at the growth stage of 0-3, 3-6, 6-15 and above 15 months was reduced by 43.5%, 41.2%, 43.5 % and 42.6% respectively compared to the normal single sprinkler head. Thus, the modified combine sprinkler heads covers the area with shorter set time. When the modified combine sprinkler heads were rotating together they have combine discharge and resists wind drift effect, so that they creates good application uniformity relative to the normal single sprinkler head at current working condition (Table 5).

Comparison of the normal and modified combine sprinkler heads

| Can growth age (month) | The normal sprinkler | The modified combine sprinkler heads | ||||

|---|---|---|---|---|---|---|

| Sprinkler set time (hr) | Sprinkler positions | Area coverage (ha) | Sprinkler Set time (hr) | Sprinkler positions | Area coverage (ha) | |

| 0-3 | 23 | 16 | 0.518 | 13 | 28 | 0.907 |

| 03-Jun | 34 | 11 | 0.356 | 20 | 18 | 0.583 |

| Jun-15 | 46 | 8 | 0.259 | 26 | 14 | 0.454 |

| Above 15 | 68 | 5 | 0.162 | 39 | 9 | 0.292 |

The normal sprinkler head at 0-3, 3-6, 6-15 and above 15 growth stage has the sprinkler positions and area coverage of 16, 11, 8 and 5 and 0.518, 0.356, 0.259 and 0.162 ha respectively. Whereas within the same design irrigation interval of 15 days and 18 *18 m sprinkler spacing, the modified combine sprinkler heads at 0-3, 3-6, 6-15 and above 15 growth stage has the sprinkler positions and area coverage of 28, 18, 14 and 9 and 0.907, 0.583, 0.454 and 0.292 ha respectively. Therefore, the modified combine sprinkler heads has approximately double sprinkler positions and area coverage than the normal sprinkler head. The modified combine sprinkler heads is better to cover the area with short time and better amount with relative to the normal single sprinkler head. If the labor cost is paid per sprinkler position, the modified combine sprinkler heads will have additional cost, even so relative to percentage of yield improvement the extra cost may not have a significance value, it has further to seen [8].

The sprinkler discharge of the normal single sprinkler under the existing working condition of 2.5 bar hydrant operating pressure was 0.56 m3/hr, whereas the modified combine sprinkler heads under the same hydrant operating pressure was 0.98 m3/hr. having this higher discharge the modified combine sprinkler heads had a tendency to resist wind drift effect, so that it had more surface area wet and uniform distribution of water relative to the normal sprinkler head.

Based on the result obtained, the comparative advantage of the modified combine sprinkler heads is the shorter sprinkler set time.

Relatively, it had a tendency to wet the surface area with short time and with better water application uniform. Also it has comparative advantage in low pressure operating fields, dry spots and wind affected fields. It has its own limitation that it needs additional fittings like HDPE pipe around 50 cm, saddle, adapter, riser power valve, it may has load effect on the main riser stand and it will have extra labor cost if sprinkler shift position is paid per sprinkler position. In general, as the field measurement taken and result obtained the system is working below the design hydrant operating pressure and sprinkler discharge of 4 bar and 1.8 m3/hr respectively which is in compliance with the study undertaken by Abshiro FK.

• The modified combine sprinkler heads is suggested to operate with the sprinkler set time according to the Table 4 with respect of growth stages at 2.5 bar and nearest 2.5 hydrant operating pressure.

• To cover the irrigated areas with the shorter set time, with low pressure operating fields, with wind drift affected areas, to fill and recover dry spot areas soon the modified combine sprinkler heads has better comparative advantage.

• In order to expand to large areas it has to be further verified with irrigation uniformity parameters, different hydrant operating pressures especially above 3 bar, at different wind areas and field management, and with overall comparative advantages.

In general the study also showed that the system is working under the design capacity of 4 bar hydrant operating pressure so that the system needs further to revise.

[Crossref]

[Crossref]

[Crossref]

Irrigation & Drainage Systems Engineering received 835 citations as per Google Scholar report